| 329 12 volt battery conversion Converting the twin 6 volt batteries to a single 12 volt unit has a number of advantages - one single 12 volt is less expensive than two 6 volt batteries and 12 volt battery technology seems to have moved on so more powerful sealed units are now available, but also you can remove those wretched "top-hat" terminal connectors which are a cause of many difficulties. Now this conversion is by no means original but here Victor Smith describes how he carried out the change. See also the earlier V8NOTE250 by Gordon Hesketh-Jones. (Jun 05) Why is the

conversion worth doing?

Dimensions of the Exide Ultra options - 063 (top) and 065 (below) (Source: Exide website)

The next consideration is deciding how best to adapt the battery leads which of course are intended for a twin 6 volt set up. The solution is to connect the redundant pair of battery terminals in the offside battery box and use the existing leads in the nearside. On fitting the Exide 063 you will find the original earth lead is around an inch or so too short for a convenient fit so you will need to fit a new 9" (22cm) braided earth lead.  New braided earth strap is fitted to the battery. (Photo: Victor Smith) The next task is the removal of the wretched lead top-hat connectors - the source of a great deal of woe for many enthusiasts as the inside face is chamfered to match the chamfer on the 6 volt battery terminals.  Cutting off the "top hat" connectors is tedious but satisfying to rid the V8 of a regular source of starting and misfiring troubles. (Photo: Victor Smith) |

.

Over time

with enthusiastic cleaning and removal of the "crust" that

can build up on the inner surface of these connectors, you can see

the profile of the chamfer changes which develops a mismatch with

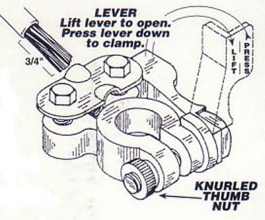

that of the battery terminal. . Anyway that is history now because you can take a hacksaw and cut them off! Using a Mole grip or clamp to hold the cable connector you make a cut into the connector and then prise the cut open and eventually the lead connector falls away. It is fair to say this is a very tedious task made worse by the cramped position of squatting in the small space behind the passenger seat but there is a bonus - as you have to replace the earth lead as it is too short with a new 10 inch braided earth strap with ringed spade connectors fitted at either end, you will not need to cut off that connector. Simply set the original earth lead to one side and use a new braided strap, so that reduces the number of connectors you need to cut off from four to three! Quite a bonus because after cutting off three connectors the prospect of cutting off a fourth is not welcome at all! You can now fit two new battery terminal clamps to the leads in the nearside battery box. My preference is for the quick release clamps which are particularly convenient. Once you have had them you will not want to go back to the bolted variety. In the offside battery box you can fit the ordinary bolted pattern of clamps as they are simply to be bolted together. However using inline brass connectors is neater - see below.  Epoxy coated quick release terminal clamps. (Source: East Penn Manufacturing Co Inc) Auto batteries must be securely fixed and not left loose, so how do we fix the new 12 volt? First you will find that whilst you can use the rear angle upstand on the battery box floor, the front upstand is positioned for the 175mm 6 volt battery so obstructs the 063. You need to gently but firmly flatten that front upstand with a 4lb hammer and solid timber dolly so that the flattened upstand is both flat and neat. Next the existing "pegs" and angled clamping plate which are used to hold the 6 volt battery need to be revised.  New battery clamping "pegs" will be needed. (Photo: Victor Smith) New "pegs" with a slightly longer threaded section need to be obtained and then using a rubber pad, the clamping bar is placed across the middle of the 063 battery and bolted up in the usual way with a plate washer, a nut and lock nut. You will also need to fix a hardwood or rubber block (about 5 to 6 cm wide) between the front face of the battery and the front face of the battery box just in case the fixing should loosen and allow the battery to slide forward under heavy braking or impact. Connecting the battery cables in the offside battery box with a heavy brass inline connector This is certainly the neatest solution and involves the least labour! Simply tidy up the cable ends after the removal of the lead "top hat" connectors, by cutting back just a little of the protective cable cover and twisting the strands so they are compact. Then first slip on the shrinkable tubular plastic sleeve before you insert each cable end into the connector. For each cable there are two grub screws which need to be unscrewed to leave a clear passage in the barrel of the connector and then, once the cable is fully home, tightened down to ensure a firm grip on the cable. Repeat for the other cable. Then you need to pull the tubular plastic shroud over the brass connector and apply heat to shrink it onto the cables and connector as insulation. An ordinary hairdryer will do the job - mine was a Braun 1200 which took around 12 minutes on the maximum heat setting at each end of the sleeve on a moderately warm day. A prudent precaution before applying the heat is to open all the doors including the hatchback to ensure plenty of fresh air is circulating as the head of the fuel pump is just below!  Tubular plastic sleeve with one end tight on the cable and brass connector after the heat has been applied. The left hand end has yet to receive the heat treatment! The result is a neat connection. You can see the head of the SU fuel pump (blue) in the bottom lefthand corner of the photo - it protrudes into the offside battery box. (Photo: Victor Smith) Connect up and test. In my case the engine fired up from cold with some enthusiasm as the Exide Ultra specification is claimed to produce 30% more starting power than the standard Exide battery. Upon reflection I feel an 065 with its better performance would have been the better choice and would have fitted in the nearside battery box. I shall make the change to an 065 when the 063 is moved to a small family saloon. Note: when this note was prepared and released as a new V8NOTE a selection of items to help carry out the conversion was available in a plastic box supplied by the V8 Register. The stock of those parts was taken up by fellow members and since then the kits are no longer available from the V8 Register. |

||||||||||||||||||||||||||||||

www.manorgaragewantage.co.uk 01235 767751 Manor Garage in Grove near Wantage in Oxfordshire offers a useful twin 12V battery conversion kit. |

12

Volt Battery Conversion Kit This kit had the good quality parts you need to do the conversion. It was available to save fellow members hunting for them. The late John Targett sourced the "J"pegs and quick release battery clamps in the US where he lived at the time. What was in the kit from the V8 Register? > Two shorter "J"pegs with plate washers, Nyloc nuts and washers for use with the existing battery clamp. > Two quick release battery terminal clamps with a protective epoxy coating. > One new earth cable. > Two heavy brass inline battery cable connectors each with four grub screws and a heat shrinkable plastic insulating sleeve. > Hardwood dolly for flattening the angle upstand on the battery box floor. > Detailed conversion and fitting instructions. Note: the 12 volt battery was not included! That is a separate purchase. |

||||||||||||||||||||||||||||||

|

See

our Information Gateways

More on 12V battery conversions More on battery maintenance & conditioners |

|||||||||||||||||||||||||||||||

|

V8

Register - MG Car Club

|

|||||||||||||||||||||||||||||||