535

Fitting

a dual circuit brake servo to an MGBGTV8 conversion

As part of the

conversion of his MGBGT to V8 specification in 2008, Mike Howlett fitted

dual circuit brakes to a 1969 chrome bumper MGBGT using the In-line Master Cylinder

and Servo. Here Mike describes the job.

One of the improvements that I

decided on early in the planning of my MGBGTV8 Conversion was to use the late

model twin circuit brake master cylinder with a direct acting servo. Accordingly

I purchased from Andy Jennings a complete late model pedal box with cylinders,

servo and pedals. This cost me £45 in 2006. I stripped the assembly down,

and cleaned and painted the parts. A new brake master cylinder was bought, but

for the servo I simply dismantled it, painted the case and reassembled it using

a servo repair kit. As the inline servo does not have brake fluid in it, the internal

components were in excellent condition. There is an issue with the clutch master

cylinder, but I'll come to that later.

Holding the new pedal box up to

the car showed that the bolt holes are in the same places, so no extra drilling

would be required for them. However, the brake pedal is hung in a slightly different

way and fouls on the rear of the original square aperture. I extended the aperture

rearwards by 30mm to give clearance (see photo).

Bolting the servo to the

pedal box and offering it up showed that there was a small area of conflict with

the servo body and the inner wing. A little dressing with a hammer soon gave sufficient

clearance.

When I was finally ready to fit the pedal box I found that

both pedals together will not go through the aperture from the top. On the bench

I removed the |

clutch pedal, bolted the servo on the box and connected it to the brake pedal.

I bolted the clutch master cylinder to the back of the box. Then I manoeuvred

the brake pedal through the hole, fiddled the rubber gaskets in place under the

box and bolted it down. This was a bit awkward as some of the bolts are in the

narrow gap between the pedal box and the inner wing. Then I introduced the clutch

pedal from beneath. You can either use an assistant to push it up, or haul it

up on a piece of wire as I did. I bolted the clutch pedal in place and connected

it to its master cylinder.

The brake master cylinder bolts on the front

of the servo and fits under the bonnet line nicely. I found that on my car, the

manual bonnet prop did not get in the way. If you have a telescopic prop, you

might have to move it to the left side of the car as the factory did.

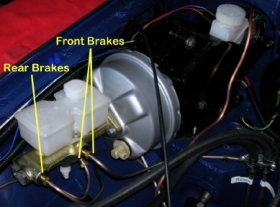

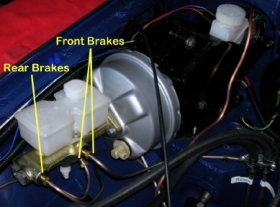

The

cylinder has three outlets, two in the first stage and one in the second stage.

I connected the two front brakes to the twinned

outlets, and the rear brakes to

the second stage outlet. This way if one circuit fails I should still have either

front or rear brakes working (see photos alongside).

|

The

tandem master cylinder has two chambers: the front chamber feeds the rear brakes

with a single pipe. Rear chamber feeds the front brakes with two pipes, one to

the right and the other to the left.

There is a circuit failure

switch incorporated in the master cylinder - it's the white object you can see

beneath the cylinder. It is up to you whether you connect this up. Personally

I reckon you would instantly know that a circuit had failed by the feel of the

pedal, so I haven't bothered.

This pedal box also has a mechanical stop

light switch actuated by the brake pedal. Again you can decide whether you want

to use this or continue with the hydraulic item, if that is what your car has

fitted as standard. The pedal switch needs to be adjusted to make sure it doesn't

prevent the pedal from returning fully to its rest position. Details are in MGB

workshop manuals.

Mike

says "this is how my car is connected up and makes sense, because if one

circuit fails you would be left with either both front brakes or both back brakes

so the car could be stopped without danger of a swerve."

See

the full article. More

Posted:

180118 |