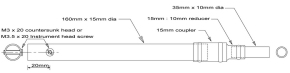

| 487 Failed oil feed to rockers Chris Ward has had his MGBGTV8 comprehensively restored (see his rebuild report) but during the work the engine had not been run for some time. He reported a problem with the oil feed and through a former BL trained mechanic learnt of the need to prime the oil pump. (May 15) Chris Ward posted a brief note on the V8BB saying "A poor oil feed to the rockers is well recognised in poorly maintained engines. Mine had been assiduously maintained by its previous owner but had stood for several years before a body rebuild. No oil supply to the rockers was noted despite an absence of "sludge". A chance encounter with a retired BL mechanic who specialised in V8s resolved the problem. The oil pump may need to be primed if the engine has been standing for a long time. A special tool is available from Rimmers to facilitate this." A similar oil pump primer tool is also available from Real Steel. Mike Howlett with an MGBGTV8 conversion added "You don't need a special tool. A piece of 15 or 20mm bar /tube or a long bolt with a slot in the end does just as well. Take out the distributor, fix tool in your electric drill, connect to the oil pump drive and spin. Make sure the drill is going in the correct direction - I can't recall whether it's clockwise or anti-clockwise off the top of my head." Geoff King with a V8 Roadster conversion noted "It is perhaps worth mentioning that the early Rover V8 engine as fitted to the GTV8 has an oil pump with a female slot, later engines from the mid 70’s and including those fitted to the RV8 have a male drive. An old screwdriver with the handle cut off can be used for the early pump and a ½” or metric equivalent piece of tube with the end flattened to form an oblong hole for the later pump. The direction of rotation is clockwise looking down." Bob Owen recalled an earlier V8NOTE430 he had contributed in May 2011 with a sequel from Pete Jevons which followed an initial V8NOTE201 from Peter Berry in May 1991 and another - V8NOTE206 - soon after from the late Brian Field. They are reproduced here as a convenient reference. What does the oil priming tool look like? Bob Owen described his oil priming tool he cobbled together when he was doing a V8 engine. It's for the slot drive standard factory V8 engine. The materials are odd bits of domestic copper plumbing with the drive by an M3 thru screw. The 15mm/ 1/2" pipe locates the tool over the drive shaft and the cross screw goes into the drive slot. The most convenient driver is a battery pistol drill. Use some vaseline around the pump gears if this is newly fitted. Run the drill until the oil gauge registers a reasonable pressure." Nic Houslip mentioned "when I rebuilt my V8 earlier this year I bought the Real Steel tool and with the aid of my beefy B&Q budget priced ½” electric drill ran the oil pump to build up oil in the rockers, but it does take a long time to get a flow of oil through. The priming is helped by filling the lifters as well and I packed them with Vaseline as well. In the event there is no tool available, you might want to remove the wire to the fuel pump in the boot , the live feed to the coil and the spark plugs, then crank the engine which should do the job. The the lack of fuel and ignition will remove the load on the engine. You will need a well charged battery." Alongside are the earlier V8 Workshop Notes on the V8 pump priming topic - they are 201, 206 and 430. | 201 Problems with the oil pump Peter Berry (Teal Blue 0201) from Kent contributes this useful note following problems he came across following a leaking oil pump base gasket. (May 91) The oil pump base had been leaking for some time and was getting steadily worse. The steering rack and front offside suspension had oil droplets hanging from their lowest points. The oil pump base was removed to allow a new gasket to be fitted. Whilst it was off, the opportunity was taken to replace the oil pressure release valve and also have the mating faces machined level again since there was about 0.003 inches wear pattern from the gears. Upon reassembly, the advice in the workshop manual was followed and the pump was packed full with petroleum jelly (Vaseline), the compressible washers were renewed and the pipes were filled as far as possible with new engine oil. The spark plugs were removed from the engine and the engine was turned over on the starter - result no oil as the pump had not been primed. Consequently the next stage in the manual was duly followed - the pipe leading from the filter to the cooler was removed and a funnel, connected to a length of old washing machine rubber hose was inserted. The funnel was filled with oil and the engine was hand cranked backwards. If you have ever tried this then you will know how difficult this is, and how easy it is to skin your knuckles! Again still no oil pressure - it was obvious that more pressure would be needed and it was decided to resort to an ordinary tyre foot pump connected to the oil filter to oil cooler pipe. Care is needed here to ensure that the pressure does not blow the hose off resulting in everything getting covered in oil. After a few strokes of the pump, the hose was topped up with more oil followed by further pumping. During this process, it is possible to hear the oil being forced through the pump. Everything was then reconnected and the engine turned over on the starter once more - this time with oil pressure achieved! 206 Priming the oil pump Brian Field (Harvest Gold 0097) from Cardiff, who campaigns a rally prepared prototype MGBGTV8, has sent in a brief note which follows up the earlier note from peter Berry (V8 Workshop Note 201) in the April issue of Safety Fast! with his own technique for priming the oil pump on the MGBGTV8. (May 91) Remove the distributor and fit your Black & Decker with a blunt screwdriver blade. Insert the blade into the drive slot from the oil pump and give it a few seconds burst, which will produce around 60psi oil pressure and then replace the distributor. 430 An oil pump priming tool Bob Owen provides a refinement of an idea posted by the late Brian Field as V8NOTE206 in May 1991. (Apr 11)  Having replaced or serviced your oil pump, the manual recommends packing it with Vaseline to assist priming. But running an engine, possibly with a new camshaft, tappets or other bits, relying on initial lubrication and waiting an age for the oil pressure to build is stressful and possibly damaging. Normally the V8 pump is driven by the | distributor

which is itself driven by a bevel gear from the crankshaft. Assuming the distributor

has been removed, Brian recommended driving the pump via the distributor hole

with a suitably long screwdriver shaft attached to an electric drill. This allows

you to prime the pump prior to cranking the engine. This seemed an excellent idea but I was concerned about aligning the screwdriver in the drive slot and keeping it there, so I built a "plumbing scrap-bin special tool". I used an offcut of 15mm copper pipe about 170mm long as the main drive, with an M3.5 screw through centrally about 20mm from the end, tapped and soldered in place (tapping is probably not necessary). M3.5 screws are the type used for securing domestic socket and switch plates. To be solderable it needs to be a brass or nickel plated brass type, not zinc plated steel. If you have a plated steel type (if it's magnetic it's steel) then just secure it with a nut and shake-proof washer. In use the pipe slips securely around the oil-pump drive shaft and the screw engages in the drive slot. To get the size down for easy driving from an ordinary electric drill/screwdriver I used a 15mm to 10mm pipe reducer with a short stub of 10mm copper pipe, all Yorkshire (soldered) joints for compactness. Lock the 10mm section in the chuck of your drill/screwdriver, slip the end over the pump shaft and slowly rotate to engage the slot. Then give it some extra speed. With this arrangement it's safe and easy to run up the pump and get to 60psi on the oil pressure gauge. Keep it going for a minute or two after pressure has built. After having done this, and of course, re-fitted the distributor, I started my refurbished engine and had all but one of the new tappets quiet from the outset and the one noisy one quietened after 30 seconds. Some have reported needing to run the new engine for up to 20 minutes before new tappets have quietened. I was also much more comfortable about lubrication of my new camshaft. Bob's

V8NOTE was originally posted on the V8 Bulletin Board and a subsequent posting

from Pete Jevons highlighted there is a kit available from a company called Real

Steel. Pete

Jevons said "you may be interested to know that the tool you made to

prime your V8 oil pump is available from "Real Steel" an engine tuning

supplier based at Cowley in Middlesex (01895 440505). They offer two types for

the different distributer drives. |

| V8

information and support See our popular V8NOTES listing, information gateways, top tips, spares and services specialists and spares for sale and wanted. | V8

Workshop Notes Information Gateways Top tips for new V8 enthusiasts | Technical

topics Spares & services specialists V8 spares for sale and wanted |