390

Battery conversion cures

V8 hot start problem

Bob Own provides a

sequel to his recent V8NOTE388 on how he solved a

hot start problem. (Oct 08)

The

problem

For some time my V8 has been giving some starting problems when

hot. I had cured an ignition problem that caused the engine to stop when hot -

see V8NOTE388 - but this second problem was a "lazy"

starter which gave inadequate cranking speed when the car was very hot, although

it gave adequate cranking speed when cold. A typical engine needs to crank at

more than 90 rpm to start.

Why should it occur only when hot?

The V8 starter and solenoid are close to the exhaust and so can get very hot if

the car is idling or in slow moving traffic, especially in hot weather. A heat

shield was fitted by the factory but often this is corroded or missing. Clive

Wheatley does an excellent aftermarket RV8 heat shield which can be used on an

MGBGTV8. You need to use a cut down fixing to allow you to fit it with the exhaust

in place. However, the heat shield is only partly effective in reducing the temperature

of the starter/solenoid. When the copper windings get hot the resistance increases

and the current passed for a given voltage decreases. The solenoid thrust and

the starter torque are both proportional to the current passed. The resistance

of copper is proportional to the absolute temperature (0C is 273 absolute or 273K).

So in going from 17C - 100C (290K to 373K), the resistance goes up by nearly 30%

so the starter torque/thrust drops by 30%. If you compound that with a less than

pristine battery that has a cranking voltage that may also be down by 30% then

you have only half of the design torque or thrust. You might think that half full

power should be enough, but this overlooks the two stage operation of a pre-engaged

starter motor.

Pre-engaged starters

When the starter relay

feeds current to the starter solenoid as a result of you turning the starter key,

two solenoid windings are energised, one in parallel with the battery and one

in series with the starter motor. The one in series with the motor passes quite

a high current and will cause the motor to rotate slowly while the solenoid operates

the lever that pushes the starter pinion into mesh. When the pinion is fully in

mesh and the solenoid is at the end of its travel, the main starter contacts are

closed causing the battery to connect direct to the starter and the full starter

power to be developed. Inadequate current through the solenoid, tightness of the

solenoid or damaged solenoid contacts may prevent correct operation of this final

stage.

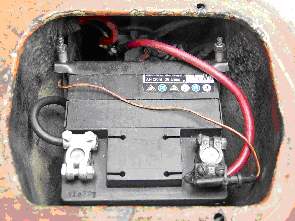

Driver's side battery compartment

viewed from rear. The battery isolator is just visible near top of picture; thin

fused lead feeds the alarm so that it still operates with the isolator OFF.

Curing the problem

When exhibiting "lazy cranking",

with the final stage of connection not being reached, if the V8's batteries were

jumped to another car's battery (usually poor Malcolm Sayers when I was in Italy!)

the starter would zip away and the car would start straight away. So at least

I had identified that a significant part of the problem was insufficient "welly"

from the batteries. I resolved to sort this problem when I got home. I would change

the batteries first and then, if necessary, do something about the starter/solenoid

- not something to be considered lightly on the V8.

Original 6V batteries

The factory MGBGTV8 was originally fitted with two 6V batteries connected in series

to give 12V. This is the same arrangement as in the 1.8 MGB of the time. However,

the V8 engine requires about 50% more starter torque than the 1.8 model, so starting

is likely to be more "iffy", even without the effects of high exhaust

temperatures on the starter/solenoid. Whilst preferring originality if possible,

I was getting a bit fed up with the 6V batteries. These were less than 3 years

old and already tired; and they're not cheap. So I decided to weigh up the pros

and cons of various approaches.

6V in series versus 12V in parallel

At first sight there would seem to be little advantage in using two 12V batteries

in parallel over two 6V in series. Other things being equal, the same volume of

battery would have the same energy storage. However, most development in the last

40 years has been on 12V batteries so the 6V batteries are still essentially as

supplied in the 1960s, whereas there is a wide choice of modern more advanced

12V batteries.

Another factor which is often overlooked is the effect

of imbalance between the batteries. Batteries are charged by the alternator to

a fixed "fully charged" voltage. This corresponds to about 2.4V per

cell or 14.4V for the 6 cells of a 12V battery. Each of the cells should have

the same capacity and then they will become fully charged after the same amount

of current has passed. If some cells become charged before others the higher terminal

voltage will reduce the voltage available to the other cells leaving them undercharged.

In a single 12V battery all the cells are manufactured together at the same time

and are likely to be closely matched. With two 6V batteries, although nominally

the same, the batteries may differ by the full tolerance range of the production

process.

A usual electronic rule of thumb is that components manufactured

together will only have one tenth of the full production spreads. So your two

6V batteries could have significantly different capacities. Connected in series,

the low capacity or "poor" one would charge first and prevent the higher

capacity or "good" one from ever becoming fully charged. A lead acid

battery degrades if it is not kept fully charged, so if you have a situation where

one of a pair of batteries is not getting a full charge then that could have a

damaging effect on that battery.

Batteries in parallel must have the

same terminal voltage, so it doesn't matter if they have unequal capacities: they

will both be fully charged when the terminal voltage reaches 14.4V. So it looks

like there are good reasons to choose two 12V in parallel rather than two 6V in

series.

The

Kai Knickman 12V battery conversion

Kai Knickman did a 12V conversion

using two 12V batteries in parallel which he wrote up in V8NOTE357.

This appealed to me as, unlike the single 12V battery conversions, it involved

no modifications to the battery box and it gave more power. Kai used two Bosch

4FN batteries. However, he cautioned that you had to live with the fact that the

batteries in the back were designed for use in a Fiat Panda! Kai, it's even worse

- my internet searches reveal that this size of battery is also used on the Piaggio

Ape (the Italian "Tuk-tuk")! Ah, well; never mind. In fact the battery

is used on several Fiats - for example the

Fiat Punto Mk2 1.2, |

Cinquecento, Panda 1.1 and 1.2

2004 on, the Seicento 1.1

and Bravo/Brava 1.4. It is also used on the Citroen C1, C2 and C3 1.1, Peugeot

107 and 1007, and Toyota Aygo, so it should be widely available. The batteries

are made by several manufacturers and the size is given variously as 002L, 202,

002FS or DIN54059 - I was surprised Kai didn't quote the latter!

Prices

vary from about £30 each for the cheapest brands to around £60 for

the dearest. With batteries you largely get what you pay for. The dearer batteries

tend to have a three or four year warranty. I opted for Yuasa "Pro"

202s which my local motor factors sold to me at £83 for the pair - that

was with a discount for two! A comparison between the original 6V and Yuasa batteries

is given in the table below.

| Parameter |

Original

6V | YUASA

202 | Variance |

Size

length (mm)

width (mm)

height (mm)

|

175

175

200

|

175

175

175

|

height

is

25mm

lower

or -8% | | Volume

(litres) | 6.125 |

5.36 |

-12.5% |

| Weight

(kg) | 11.5 |

10 |

-9% |

Capacity

Total Ah | 56 |

70 |

+25% |

Energy

density

Wh/litre | 110 |

157 |

+42% |

| CCA*

total | 270 |

480 |

+78% |

| Warranty

(yrs) | 1 |

3 |

+200% |

| Total

cost | £124** |

£83 |

-33% |

CCA = Cold

cranking Amps, roughly the current the battery can deliver for 1 minute at sub

zero temperatures before its terminal voltage falls below 1.4V per cell (approximately

8.5V for a 12V battery). At low temperatures the current generating chemical reactions

within the battery proceed more slowly. The CCA is the key measure for starting

ability - more useful than straight capacity. Capacity is more useful, for example,

in working out how long the battery would run your lights.

** Moss

price, excluding carriage.

The table indicates that the two 12V Yuasas

vastly outperform the original two 6V batteries arrangement showing their superior

technology. What is more they do this at a cost which is a third lower and have

a longer warranty. No contest really . . .

View of new batteries from

the front. The isolator switch is lower left; new earth strap is upper right of

the driver's side battery compartment. Original earth strap used in the nearside

compartment.

Installation

notes

Remember that for safety the first thing you do is remove the earth

lead from the old batteries and the last thing you do is connect the earth leads

to the new batteries.

Many years ago I fitted a battery isolator switch

to the bulkhead in front of the driver's side battery, so my installation was

a little different to that on Kai Knickmann's V8. Like Kai, I concluded that the

best layout was with connectors at the back with an additional earth strap to

the existing hole at the back of the driver's side battery compartment. When making

that connection, remember to get down to clean metal - I used a cup type rotary

wire brush in an electric drill. However, I decided to take my second positive

battery lead from the isolator so this lead was to be terminated by a large crimp

ring connector at the isolator end and the battery clamp at the other. Lacking

a suitable crimp tool, I stripped the red heavy duty cable and inserted it in

the crimp ring sleeve and then "crimped" it by using the body of a 5mm

drill laid across the sleeve at right angles and then squeezing them together

in a vice. You can test this by putting the ring end in the vice and seeing if

you can pull the cable out. The cable is then cut to a generous length and a suitable

rounded pen top is pushed over the cut end to facilitate pushing it through the

corrugated conduit linking the two battery compartments. Then cut to length, strip

the end and connect the battery clamp. You can use the same "crimping"

technique on the earth strap if you are not using a pre-made one. A pre-made cable

cannot be used for the positive link as it will not go through the cross tunnel

conduit.

To fix the batteries I adopted Kai's suggestion of cutting down

the J bolts and using a spacer to allow for the reduced battery height. I used

sawn off lengths of 10mm dia 1.6mm aluminium tubing (from B&Q). The J bolts

now fix on the front side of the batteries.

Before and after

With the original batteries and a hot engine, the

solenoid would fail to switch to full power after engagement and the resulting

slow crank was insufficient to start the engine. Even at lower temperatures the

slow initial crank was often evident before relief at the onset of the fast crank

at which the car started. With the Kai Knickman twin 12V in parallel set up, the

fast crank appeared to be immediate and the car starts with no problems at all.

If after a long rest, there is the usual V8 short period of cranking as the inlet

manifold fills with fuel air mixture. Not having an instant start is not a problem

as this helps oil pressure to build prior to fast running. When starting the car

after hot from recent running, the start is almost immediate. My existing starter/solenoid

is performing just fine with the new battery set-up so the need to cross this

bridge with replacements is now sometime into the future.

A recent email

from Kai confirms that his new 4 litre high compression engine he has fitted also

starts easily even in the coldest weather. A few measurements show why there is

such a big improvement. The actual steady state cranking current from the Yuasas

was measured at 180A at 20C ambient with a cold engine (king lead removed to prevent

ignition). At this current there was 0.4V drop in the starter feed cable. The

original batteries produced an initial 8.8V at the starter under these conditions,

so were clearly down from their specified CCA. The Yuasa batteries produced 10.8V

at the starter. So, from an initial fully charged off load voltage of 12.8V the

original batteries dropped 3.6V under starter load whereas the Yuasa batteries

dropped just 1.6V - a dramatic improvement. The 23% higher voltage at the starter

makes a big difference; 23% higher voltage gives 50% more power.

Conclusion

I am delighted with this conversion and would strongly recommend it. It gives

much better starting performance, higher capacity, lower cost and likely longer

service life and involves no fundamental modifications to the car. These modifications

could easily be returned to the original set up should exact originality become

an issue. It has no downside. |