|

232 Heavy steering

has been a noticeable feature of the MGB and the MGBGTV8 models

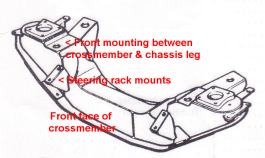

The B&G Castor Reduction Kit is designed to do two things - first to reduce the castor angle by 3 degrees from the original 7 to 4 degrees and second to maintain the integrity of the mounting of the crossmember to the chassis leg. It is worthwhile understanding how this new kit achieves that with well thought through engineering details which ensure the mounting bolts continue to be positively located in taper seats in the chassis legs and the rubber mounting pads are not crushed to achieve an accurate castor angle setting. This is seen as an improvement on another kit currently available, which when fitted results in the taper of the bolt being held away from its seating and the rubber pad being crushed when the assembly is torqued up. How is the

crossmember mounted to the chassis leg before the castor modification?

|

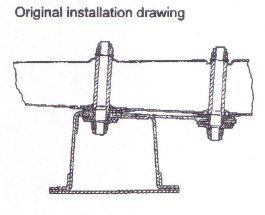

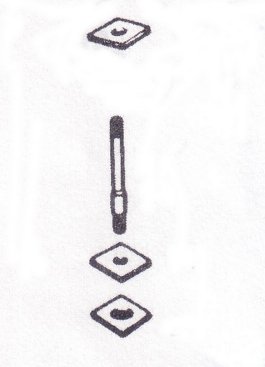

Mounting bolt with upper pad, lower pad and steel plate with the locking nut under. Note the mounting bolts have screw threads at the top and bottom and a thicker plain section in the middle, with a taper at the top. (Diagram: V8 Parts Manual) by the bottom locking nut. The pressure on the rubber pad between the chassis leg and the crossmember is therefore limited so crushing is avoided. How does the kit reduce the castor angle? The method used to reduce the castor angle is to rotate the crossmember towards the front of the vehicle by providing a precisely stainless steel packing piece between the front crossmember fixing points and the underside of the chassis leg. Since the steel packing has used some of the length of the plain portion of the mounting bolt, a steel collar is supplied with the kit which has to be fitted. In effect it extends the plain portion of the mounting bolt back to its original length. Without this collar the rubber mounting pads would be compressed too much thereby ruining the mounts and the ride quality - and of course the crushing would give rise to variances in the castor angle, even between each side of the vehicle. New slightly shallower high tensile steel locking nuts are provided in the kit to fit the reduction in useable thread length of the mounting bolts. Steering rack packing pieces Because the angle of the crossmember upon which the steering rack is mounted will have changed slightly in relation to the chassis legs, the body of the steering rack mast will quite probably no longer align with the steering universal joint. The steering rack mounts will therefore have to be packed at the front in order to realign the rack with the universal joint. Six packing shims are included in the kit. Can a V8 enthusiast fit the kit? The B&G Castor Reduction Kit can be fitted by a competent DIY mechanic but as with most matters relating to vehicles, the modification does need to be carried out with the right equipment and conditions and sufficient knowledge, mechanical skill and aptitude. If you have any doubts whatsoever, the kit should be fitted by a professional mechanic. B&G estimate that fitting the castor reduction kit requires approximately three hours work. Now a few cautionary notes regarding RV8s and Heritage shells and crossmembers There is a mistaken belief about that the castor angle on the RV8 is the same as the MGB and V8 and so the castor reduction kit can also be fitted to the RV8. This is incorrect as the castor angle on the RV8 is 3 degrees 48 min +/- 54 mins (see the RV8 Repair Manual AKM7153ENG) so using a castor reduction kit that would remove 3 degrees of castor would leave only 0 degrees 48 mins +/- 54 mins which is not sufficient. In addition the crossmembers supplied by the British Motor Heritage plant at Witney, whether supplied individually or incorporated in new BMH shells, already have a reduced castor angle. BMH have confirmed that the castor angle reduction was incorporated on the crossmembers they supply. Therefore any MGB or MGBGTV8 fitted with a Heritage crossmember, or even in some rare cases fitted with an RV8 crossmember, should NOT be fitted with a castor reduction kit. Prudent check for cracked steering rack mounts While you are working in this area on fitting the castor reduction kit, it is well worth checking the condition of the steering rack mounts for any hairline cracks or more serious fractures. These have been reported in detail together with the information on the new strengthening gusset supplied by B&G. See V8NOTE338. A routine check on the condition of the mounts should be included in your annual servicing checklist. The B&G Castor Reduction Kit (AHH6195 CASTOR) is available now from stock at £29.95 including VAT. The kit includes comprehensive fitting instructions and detailed diagrams. The Steering Rack Mount Strengthening Gusset (AHH6195 BRACKET) is also available from B&G. They can carry out the inspection for you and if cracks are discovered, supply the gusset and MIG weld it to the mount and crossmember at their Baldock workshops. For details of the new strengthening gusset see V8NOTE339. What is castor? See our technical panel in RV8NOTE231 Copyright

reserved by the V8 Register of the MG

Car Club

|