New

method of making replacement parts

Classic Car Weekly

Available on newsagents' shelves on Wednesday each week. An interesting

read with news of events, auction listings and results, reviews of

classics, technical material and cars for sale adverts. More

MGV8 parts availability

The availability of parts for the MGBGTV8 model, including mechanical

parts, routine serve items and body panels, is good from leading MGV8

parts specialists like Brown & Gammons and Clive Wheatley, but

with the limited production run RV8 it can inevitably be less so.

However on checking with Clive Wheatley he confirms the availability

RV8 spares - both rear wings, both door skins, boot lid, bonnet, front

wing (one side) and the headlamp binnacle are available. Malcolm Gammons

mentioned Brown & Gammons also have good stocks of RV8 spares

as they took over the former MG

Rover spares stocks from Catapillar some years ago.

Brown &

Gammons

Clive Wheatley mgv8parts

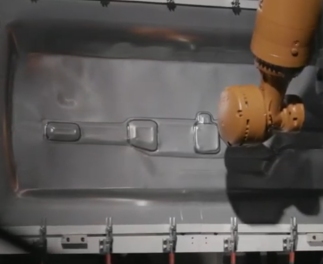

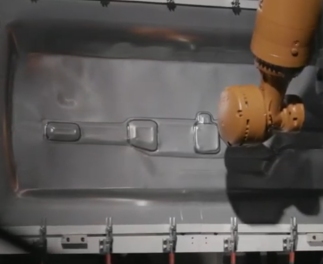

Nissan teaches robots to make replacement parts for cars

Nissan

Global Newsroom & More

See video clip

Posted: 191010 |

|

Classic

Car Weekly report that "a new method of reproducing

replacement parts - one that could recreate the panels and

metal parts for any classic no matter how rare" - has appeared

as a new innovation. CCW adds "Nissan says that a panel,

component or pressing can be remade as long as the drawings

exist. If no drawings are available but a single part remains,

it can be scanned and copied. Nissan's process, referred to

as dual sided dieless forming, is described as needing

no tooling or presses to work." Nissan says that it is

intending to reproduce parts for its heritage models in the

long-term but says it is also planning to commercialise the

technique more widely.

The response from the classic vehicles community has seen some

groups congratulating the innovators. The Federation of Historic

Vehicle Clubs (FBHVC) says "we welcome news of any new

technology that makes life easier for those restoring and preserving

historic vehicles".

Of course cost will be a concern for many enthusiasts and

replacement parts specialists and restorers but often, where

the original tooling has been lost, the front end investment

in new tooling can make the viability of a resourcing project

difficult. Where a parts specialist does go ahead with a new

parts project inevitably those costs have to be passed through

to the selling price plus the specialist, often with the cooperation

of other leading parts specialist, then have quite high costs

for holding initial stock levels from minimum economic production

runs. The new technology could help reduce both the front end

cost, the production cost of new parts and the funds locked

up in stockholding. |

|

Tony

Lake, an MGBGTV8 enthusiasts and in earlier times an engineer

with a heavy mechanical plant compamy in the UK, says "if

you google “dual sided dieless forming” there is an

excellent youtube video of the technique (see link alongside).

I suspect this is part of their rapid prototyping process for

new models after the clay styling stage. In the video clip it

looks like they’ve made a bulkhead piece. I wouldn’t

hold my breath for low costs though as there is some pretty

fancy engineering going on here. Between CAD and CAM and digital

scanning it will be easy to rack up quite a bill.

I guess owners of old cars with damaged sheet metal will still

look to the craftsman who can cut and shut so expertly. I’m

working on an Alvis TA21 at present and all four wings will

be handled like that." |

|