453

Tightening

up the sleeved wheel nuts on a Dunlop composite wheel on an

MGBGTV8

Following a recent query from a V8 enthusiast on how best to

tighten up the sleeved wheel nuts on a Factory MGBGTV8 fitted

with the original Dunlop composite wheels, Victor Smith highlights

it is well worth drawing attention to a standard routine V8

enthusiasts have used for many years.

(Aug 2012)

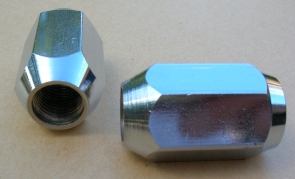

The wheel nuts used with the Factory fitted Dunlop composite

wheels (alloy centres with chromed steel rims) are a sleeved

nut. Unlike the conical faced wheel nuts used with the standard

wheels fitted to the MGB models, the sleeved V8 wheel nuts do

not self centre when a Dunlop composite wheel is offered up

to the studs and the nuts tightened up. It is poor design feature

which can result in the wheels being slightly misalinged on

the studs leading to wheel balance problems.

So when refitting a Dunlop composite road wheel it is necessary

to centre the wheel on the studs using of two standard MGB conical

seating wheel nuts acting as slave nuts on opposite wheel

studs before tightening up two sleeved V8 wheel nuts on the

other two studs. As the conical seating of the wheel nut presses

onto the outer face of the stud hole in the wheel, it has the

action of centreing the V8 wheel on the studs. Once the

two V8 sleeved wheel nuts are on and tightened up, then you

undo the two slave nuts and replace them with the other two

V8 sleeved wheel nuts. They are tightened to the recommended

torque of 60 lbf ft.

You can get hold of a pair of conical seating wheel nuts very

easily – they are the type used on the standard MGB 1800

model, part number BHH1087.

If you have your wheels removed by a tyre fitter or by a garage

mechanic who is not an MG specialist familiar with the V8 model,

then

you will need to ensure the standard routine above is followed.

Having a pair of conical faced slave wheel nuts in your small

arm rest store area will

|

Sleeved V8 wheel nut.

Pair of conical faced MGB wheel nuts for use

as slaves which can be kept in the arm rest for whenever they

may be needed.

ensure

they will be

available when needed.

See

our illustrated version of this note. More

See also V8NOTE291 contributed by Jeff Ward in August

2003 on avoiding wheel nut damage. He has some good advice on

how to avoid damage to the chrome wheel nuts on a V8 by using

a Wall Drive Socket, sometimes called a Flank or Surface

Drive, which exerts pressure on the flats of the wheel nut instead

of the easily damaged corners. V8NOTE291 |