432

Using Jubilee clips

correctly and choosing the correct size

Ian Jennings, who runs

L. Robinson & Co (Gillingham) Limited in Kent (the manufacturer of Jubilee®

Clips), provides a useful guide to using their clips and choosing the correct

size for an auto application. (Aug 11)

Anyone who has worked on a car or engine will undoubtedly have seen a number of

different methods for securing the range of hoses that can be found under a bonnet.

Most will have a preference for particular fastening methods as a result of their

experiences. A good example of this is spring clips, often favoured by manufacturers

as they are easy to fit for robots with their penchant for linear movements. They

can, however, be something of a nemesis to the mechanic who has to remove them,

often at the expense of a small quantity of his own blood. Typically they would

be replaced by something adjusted with a conventional tool such as a spanner,

a socket, or a screwdriver. There are two main types of fastener that fall into

this category, nut and bolt clips and worm drive hose clips. Although they perform

ostensibly the same task (that of securing a hose onto a fitting) they are quite

different.

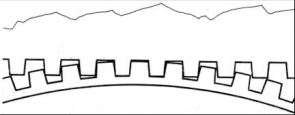

Worm drive clip

A well made worm drive clip, the

best known of which is the UK manufactured Jubilee® Clip, should provide a

vastly superior clamping force as well as a better seal under pressure and a higher

tightening torque than a nut and bolt clip. However there are issues with using

a worm drive clip on a smaller bore hose. Considering how the two products work

the reason is clear. With a worm drive clip the screw is at a tangent to the threaded

band. If the radius of the clip is too tight then it cannot engage properly and

will not work. The number of teeth that can be engaged increases with clip diameter.

Although there will never be more than one tooth fully engaged there can be several

partially engaged teeth either side of the fully engaged one on the largest sizes

of clip.

These problems are minimised with Jubilee® Clips in two

main ways:

Firstly, the teeth are finer than typically seen on other

clips (14.1 teeth per inch compared to typically 12tpi), which gives more partially

engaged teeth on all clips and specifically on the smaller clips.

The other factor is that the housings of Jubilee® Clips are pressed into

the correct radius for that size of clip. Fourteen different radii of housing

are used across the Jubilee® range which ensures a proper seal, so long as

the correct size of clip is used. Even though a clip can be tightened beyond the

correct minimum (and this can be useful to get out of a tight spot) the seal achieved

will likely perform poorly under pressure if too large a clip is used. So, a good

quality worm drive hose clip such as a Jubilee® Clip offers an excellent solution

down to 9.5mm diameter, but not below that. |

Jubilee®

Clip, the best known worm drive clip.

Nut and bolt clip

This is where the nut and bolt type clip comes in.

The nut is fully engaged around the circumference of the bolt regardless of the

size of the clip. It is still important to choose the correct size of clip because

the range of adjustment is limited by the length of the bolt; there is also a

torque induced across the bolt as it is pulled around to fit the radius it is

being secured around, which it will naturally resist. The torque that can be achieved

with a nut and bolt clip is restricted to the force required to bend the two steel

forms that hold the nut and the bolt in place, once this has been exceeded the

fastening becomes no tighter and the clip will simply deform.

Jubilee Junior, a nut and bolt clip.

A Jubilee Junior (nut and bolt clip)

has a recommended tightening torque of 1.5Nm compared to a recommended tightening

torque of 3.4Nm for the smallest (000) Jubilee® standard range worm drive

clip of 9.5-12mm. With a nut and bolt clip the recommended torque is the same

for all sizes, because it is the same nut, the same bolt and the same steel that

will deform. With a worm drive clip, where it should be the engaged teeth of the

screw and band that fail, the recommended tightening torques increase with the

number of teeth engaged, or to put it another way, with the size of the clip.

With the Jubilee® range of products there is a slight overlap in the

size ranges because, with soft hoses or plastic spigots, it may be that a nut

and bolt style clip, such as a Jubilee Junior, would offer a better seal. This

is due to the thinner band material which is less rigid and will take the shape

of the fitting at a lower torque than a worm drive clip with a thicker band would.

Usually this is the preference of the mechanic.

The most important thing

then is to select the correct size of clip. All Jubilee® standard clips and

Jubilee Juniors have the recommended adjustment range stamped on the band to make

size selection easier. With the right size of a good quality hose clip in place

the mechanic can be happy that all of his good repair work is up to the highest

standard and be satisfied in another job well done. You can see the Jubilee website

at: www.jubileeclips.co.uk/

Back

to homepage |