427

Failed

replacement rear brake adjuster

Barrie

Jones finally completed the rebuild of his MGBGTV8 and took

it for an MOT test during which he had an unpleasant surprise

- it's an important caution for fellow enthusiasts.

(Apr 11)

Barrie took Damask

450 to his local MG specialist for its first MOT. But there

was one nasty moment - when the tester stamped on the brake

pedal, there was a snapping sound and the brake pedal fell to

the floor! You

may remember that one of the brand new brake adjusters had previously

stripped a thread when he was rebuilding the brakes, well the

other one failed in a more dramatic way at the MOT test! See

Rebuild Report 31. More

The earlier failure was reported in Rebuild Report 28. More

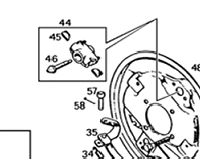

The

broken part is the rear brake shoe adjuster mechanism. See part

44 in the diagram alongside and above.

Barrie says "I

do worry that some of our new replacement parts are of very

poor quality. Anyway, the adjuster was replaced with one from

a different supplier, and Damask 450 then sailed through the

MOT."

But

when Barrie got home he began thinking about the failure and

hunted out the part that had failed earlier and together with

the unit that had failed at the MOT test compared them with

the new replacement part and the original part removed from

the car during the rebuild. Barrie noted "I found the other

brake adjuster that had stripped its thread earlier during the

rebuild. It was in my `black museum' of faulty and worn MG parts.

When comparing it to the second failure it was obvious that

they were a pair from the same manufacturer. I also dug out

an old original one and a new replacement from a different manufacturer.

I would guess that the failed ones were both made with a soft

alloy that was far too weak for the job."

Barry cannot be certain where the faulty replacement rear brake

adjusters came from but there is a distinguishing feature which

will help fellow enthusiasts identify another unit from the

same batch. He urges fellow members to avoid these replacement

rear brake adjusters as a brake failure of this type is no laughing

matter! It could be fatal. So if a replacement adjuster has

been fitted to your car in the last three years a cautionary

check would be wise.

Back to homepage |

Failed brand

new replacement rear brake adjuster

Rear brake

adjuster is item 44 in the above diagram

So what can you do to check for a possible faulty brake adjuster?

Examine the replacement adjuster - does it have a smooth

appearance on the casting?

When Barrie examined the two faulty brake adjusters the overall

appearance is a very smooth surface to the component - it looks

as if it has come out of the mould very cleanly, almost as if

it were an injection moulding. The original and good quality

units have a more "pitted" finish on the surface of

the casting. With two replacement units failing he does not

feel you can ignore this. The first adjuster had the studs pull

out bringing a "twizzle" of metal alloy with it and

the second one had the studs shear off.

Torque test the unit before fitting

Tighten the nuts up thoroughly with a spanner and if they

strip be grateful that test may have saved a life!

This cautionary

note will be added to the Top Tips for a New MGBGTV8 Enthusiast.

The cautionary tip has also been passed to the MGB and MGC Registers. |