|

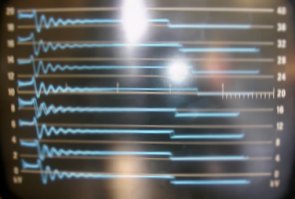

379 More on V8 distributors Gordon Hesketh-Jones (Harvest Gold 1904) from Cornwall has clocked up more than 400,000 miles in his MGBGTV8 so has had a higher maintenance workload than many fellow V8 enthusiasts. He also uses his V8 for touring in Europe so reliability is a key concern for him and one area is the reliability of his ignition system. As an update on his earlier V8NOTES on this topic, Gordon reports his experience with fitting a Pertronix electronic ignition system. (Jun 08) I first wrote about the distributors for the MGBGTV8 in V8NOTE282 in March 2003 followed by V8NOTE317 in December 2004 and then in V8NOTE365 (February 2007) reviewed the history and the various options for converting to electronic ignition thus doing away with the increasingly unreliable contact breakers. In the latter note I mentioned how dreadful the trace of both of my Holden-rebuilt distributors with conventional contact breakers looked on a Krypton analysis machine, but did not have the opportunity to compare the traces of the conventional distributor with the Pertronix replacement I had fitted to my V8 until the mini-disasters on our trip around France in January 2008. I returned from France with a conventional distributor unit in situ and then went up to see Tim Kelly - the MG specialist near Truro - for the Pertronix unit to be re-fitted. I made a point of taking my camera with me so I could record the traces on his Krypton screen. Incidentally, the normal MoT station will no longer have a Krypton-type ignition analyser as all modern cars have had electronic ignition as standard since 1993, so the Mot stations now focus simply on analysing the exhaust gas. Engine produced a 10% improvement in mpg and was much smoother The first photo of the Krypton screen shows the trace from a distributor fitted with the standard points in place. Plug No 1 is at the top of the screen, then the rest coming down the screen in firing order. On the horizontal scale it can be seen that there is a variation from 2.92 to 3.55 of the actual firing point. Note: this scale does not relate to 4° before top dead centre, it is a machine scale! The centre-line of the two extremes would be at 3.235, so the two worst cases represent |

Back

to Contents listing

variations in firing of a horrifying plus or minus 9.7%. The electronic unit takes away the variations caused by wear on pinion and cam of the distributor shaft and we no longer have to worry about contact wear or contact bounce. The engine visibly and audibly immediately runs far more smoothly when the electronic unit is working, with the further benefit that on our 721 mile round trip to Silverstone (550 miles of dual-carriageway and the rest in country lanes or stop-start motoring) we averaged 32.2 mpg - an absolute boon in these days of expensive petrol, and an improvement of around 3mpg or 10% on the figures achieved in our various long continental trips in recent years. Incidentally we had a shock-horror situation when we first reinstalled the Pertronix kit - the engine turned over but would not start!!! It turned out that the brass contact strip had come off the rotor arm. Thank goodness it happened at Tim Kelly's place and not halfway down an Alp in France - even though I obviously carry spares. It can be seen from the Krypton traces that our standard coils give out approximately 8,000 volts but these Pertronix units produce a big fat 40,000 spark leading to greatly improved combustion, more power and better running. |

||

Trace from a distributor fitted with the standard points in place. On the horizontal scale it can be seen that there is a variation from 2.92 to 3.55 of the actual firing point. |

Trace from a Pertronix distributor shows a very different picture with all the firing points totally identical. The engine visibly and audibly immediately runs far more smoothly when the electronic unit is working. |

||

| Pertronix

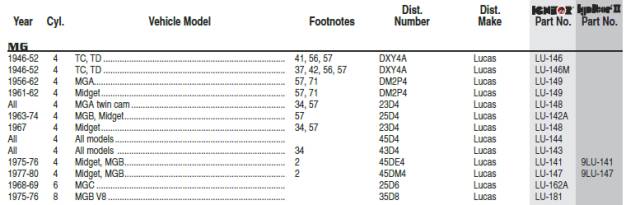

Igniters and High Voltage Coils This is an American kit using the Hall effect principle that has been in production for a wide range of vehicles for nearly twenty years. Information on their website is a bit sparse but as I understand it they provide a circular plate into which they have mounted eight magnets, with the Hall effect device contained in an epoxy moulding which also fits inside the distributor cap - so no external box is needed. Their early products were for use on VWs then on Porsches so it is no surprise to find that their UK distributor for the 8-cylinder Pertronix Ignitors is Maxted-Page & Prill Ltd of Halstead some 17 to 18 miles from Chelmsford, tel 01787 476338 (ask for Andy, also on 01787 477749) who are Porsche specialists - including racing success at the Le Mans Classic event. Their model number for the MGBGTV8 is LU181 which is priced at £79.95 plus postage plus VAT. Their high-voltage coils work out to £66 plus postage plus VAT and are designed for use with the Ignitor system. (Pricing information correct as at February 2007)

|

|||

|

|||

|

Photos:

Gordon Hesketh-Jones. Copyright reserved by the V8 Register

|

|||