349

Front windscreen replacement on an MGB Roadster

Bill McCullough (Green Mallard 4313) felt his article is really for

any MGB Roadster owner but as there is a growing number of V8 conversions

in Roadster shells, it might be appropriate to have it somewhere for

general information. (Apr 06)

Four days after

an MOT success with my V8 Roadster, I noticed a fresh crack in the

front screen, a few inches first but right across the screen within

three days. Not having replaced a Roadster screen since reshelling

this car, and that was before the actual fitting out, I looked at

various sources including the MG and Haynes manuals for guidance.

The suggestions were rather daunting and included removing the complete

dash and draining the coolant system. There is a short cut.

Top and lower windscreen surround securing bolts.

(Diagram: MGB Workshop Manual AKD3259)

Disconnect the

battery. Remove the upholstery trim below the windscreen on both

the passenger and driver sides - a total of about 10 self tappers.

Remove the glovebox (but not the actual 'door') and the small support

bracket, again about 10 self tappers. This will give you visual

and physical access to the top bolt on the passenger side

that secures the windscreen frame on the passenger's side, via the

aperture provided by the removal of the glove box - its difficult

but a 9/16" socket on a 2" extension with a universal

joint with ratchet will do the job, the lower bolt removal

is straight forward with the same socket.

Need to remove the fuel gauge on the driver's side. (Diagram:

MGBGTV8 Driver's Handbook AKD8423)

The situation

on the driver's side calls for the removal of the fuel gauge from

the dash, it can simply hang on its wiring to the outside of the

dash. Access to the top bolt on the driver's side windscreen

frame is via the aperture provided by the removal of this gauge.

The same extension and 9/16" socket are used, it is difficult

but achievable. The lower bolt is straight forward removal.

With these 4 bolts removed and the support rod disconnected from

the top of the dash (two bolts) the whole windscreen frame can be

removed from the car. Once I had worked it out, the removal took

less than 20 minutes.

Removal

of the screen from the frame was not a problem - but if at all

possible keep the old screen intact and compare it against the replacement

unit before attempting to reassemble the frame - the first screen

I tried was approx 3/16" deeper on both lower corners and although

I did get it into the screen frame I could see there would be problems

when it came to installing the assembled frame to the bodyshell

- with the screen rubber already fully compressed at two points

I was convinced that the glass would fail. Back to my friendly MG

parts supplier and a quick check on another new screen produced

a visible improvement. A refit of the replacement screen solved

the problem.

Refitting

the reassembled frame to the body has the potential to be very

difficult, but it's really a reversal of the above - that's what

they say in the manuals. First of all cut screw driver slots on

the faces the two top bolts, and in this way while you helper applies

pressure to the windscreen pillars you can use the same apertures

to apply a screwdriver and get the initial few threads entered.

The next time I do this job (not soon I hope!), I will drill out

the threads on these two top holes and use

|

the bolt and nut

technique - there is ample space to attach the nut viewed from the

door aperture, this would remove the need to get these bolts started

on the threads. There is a limited view of these top bolts if you

pull down the rubber door seal at the top where it bridges the gap

between the side of the dash and the door - you can see sufficient

to ensure your 9/16" socket is entered onto the bolt. The alternative

is to lie upside down with your head in the footwells trying to operate

a torch and spanner at the same time.

I would mention that the new windscreen rubber I obtained was not

satisfactory. It was too long by about 6" and as a result would

not stay on the glass making it very difficult to assemble the frame.

In addition the rubber did not make provision for the sharp corners

at the bottom of the screen. The old rubber which I purchased 9 years

ago, was properly moulded at the lower corners and a tight fit all

around the screen, this old rubber was reused and a smear of 'swarfega'

made the whole assembly quite straight forward.

Fitting the

rubber sealing strip to the bottom rail

All the above is good news, but there is one item of bad news and

that involves the aluminium bottom rail on the screen. Does anyone

have a shortcut to fitting the rubber sealing strip?

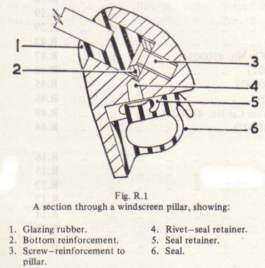

Sealing strip and the aluminium bottom rail. (Diagram:

MGB Workshop Manual AKD3259)

I spent longer getting the rubber seal fitted to

the windscreen frame than fitting the complete assembly to the car!

It is the rubber seal that fits between the screen assembly and

the car body across the width of the screen. I spent longer getting

this seal fitted to the windscreen frame than I did fitting the

completed assembly to the car!

The windscreen

removal and refit procedure described above has proved to be much

more user friendly than that suggested by the various manuals.

I found that a short ratchet with a 1/4" or 3/8" square

drive and universal joint and socket is the most appropriate. In

addition I did strip the threads on one of the bolts that secure

the central rod support bracket to the dash top - see above. Easy

to solve, pull out the two plastic fresh air vents in the middle

of the dash and you have a clear view of these two bolts and nuts.

The windscreen

I obtained was manufactured in Finland and is relatively inexpensive

at £60. However there has to be a question mark over their

quality control, so retaining your old screen for comparison could

be important. But why did my original screen break after nine years?

I have suspicions that the thick rubber seals that fit between the

quarter light and the screen uprights were too thick, causing the

whole frame to flex every time I closed the door or drove over a

rough road. New quarter light seals have been modified to ensure

they do not cause the same problem again.

I hope the above

may help solve a few problems for fellow members.

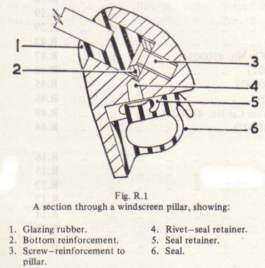

Section through the pillar of the windscreen surround

assembly. (Diagram: MGB Workshop Manual AKD3259)

|