|

340

Review of the B&G Castor Reduction

Kit

An improved castor

angle reduction kit has been produced for chrome and rubber bumpered

MGBGTV8 and MGB models by Brown & Gammons, the MG specialists

at Baldock. This note from Chris Hunt Cooke and Victor Smith describes

how fitting the kit rotates the crossmember forwards thereby reducing

the castor angle, reviews the engineering improvements, provides

some useful background information on the need for positive castor

to self-centre the steering at speed and give good steering response,

and describes how reduced castor with modern radial tyres gives

a reduced steering load. (Jan 06)

Heavy steering

has been a noticeable feature of the MGB and the MGBGTV8 models

It is caused by the 7 degrees of positive castor needed to produce

the self centring steering action with the cross ply tyres available

in 1962 when the model was first produced. Since that era radial

tyres have been developed along with improved rubber compounds with

greater grip which have the effect of increasing the steering load,

particularly with tight cornering or cornering at speed. As modern

tyres are far more directional, less self-centring force is necessary

and so less castor is required. Consequently these tyre changes

provide scope for reducing the castor angle and thereby obtaining

the welcome benefit of lighter steering.

The B&G

Castor Reduction Kit is designed to do two things - first to

reduce the castor angle by 3 degrees from the original 7 to 4 degrees

and second to maintain the integrity of the mounting of the crossmember

to the chassis leg. It is worthwhile understanding how this new

kit achieves that with well thought through engineering details

which ensure the mounting studs (or bolts) continue to be positively

located in taper seats in the chassis legs and the rubber mounting

pads are not crushed to achieve an accurate castor angle setting.

This is seen as an improvement on another kit currently available,

which when fitted results in the taper of the stud being held away

from its seating and the rubber pad being crushed when the assembly

is torqued up.

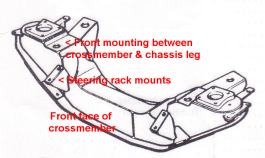

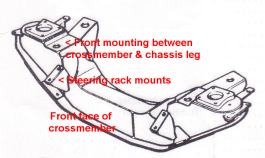

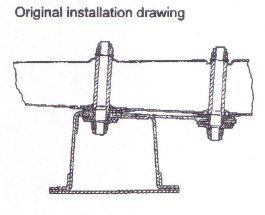

How is the

crossmember mounted to the chassis leg before the castor modification?

The MGB front cross member is fabricated out of pressed and welded

steel sheet and is mounted on the underside of the chassis legs

(which are box sections extending forwards from the monocoque) with

four high tensile steel mounting studs which are positively located

on taper seats into the chassis leg. In the attached drawing of

the crossmember you can see on either side that the topmost part

is the platform with four holes on which the lever arm shock absorbers

are mounted. Just inboard from those platforms are the two large

holes on either side through which the crossmember is bolted to

the chassis legs by the mounting studs.

Front crossmember is fabricated out of pressed and welded

steel sheet and is mounted on the underside of the chassis legs

(which are box sections extending forwards from the monocoque) with

four high tensile steel mounting studs (or bolts) which are positively

located on taper seats into the chassis leg. (Drawings: Parts Manual

and B&G)

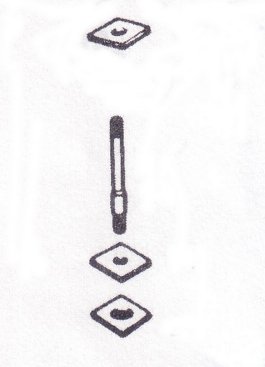

Those mounting studs have screw threads at the top and bottom

and a thicker plain section in the middle, with a taper at the top.

The intention of the design is that the taper locates to a corresponding

taper seating in the bottom of the chassis leg. Hence the mounting

bolt is positively located in the centre of the hole in the chassis

leg when it is bolted up with a torque of 56 lbft.

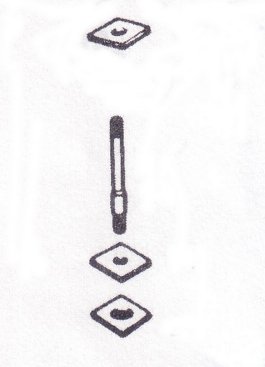

Mounting stud (or bolt) with upper pad, lower pad and

steel plate with the locking nut under. Note the mounting bolts

have screw threads at the top and bottom and a thicker plain section

in the middle, with a taper at the top. (Diagram: V8 Parts Manual)

This leaves the bottom part of the mounting stud protruding below

the chassis leg with a plain section, and beneath that a narrower

threaded section forming a shoulder at the end of the plain section.

Over the plain section of the stud is fitted a rubber pad which

acts as a packing piece between the chassis leg and the mount on

top of the fabricated crossmember. This is held up by a rectangular

washer with a smaller diameter hole so that the washer sits on the

shoulder of the plain section of the mounting stud but is held in

place by the bottom locking nut. The pressure on the rubber pad

between the chassis leg and the crossmember is therefore limited

so crushing is avoided.

|

What

is castor?

The castor angle is the angle, measured in degrees,

formed between the axis of the kingpin and the perpendicular

to the ground looking at the vehicle from the side. As the angle

is formed longitudinally relative to the vehicle, it is more

exact definition is longitudinal castor angle. In practical

terms it is known more simply as castor angle. The castor angle

given to the kingpin creates two important phenomena for the

ride and handling of the vehicle - first stability in terms

of maintaining the straight line of travel of the vehicle and

the extent to which the steering self centres after turning

and second the tilt of the wheel which occurs during turning.

The

stability phenomenon is created on the basis of the distance

between the point at which the kingpin axis extension falls

(in relation to the direction of travel) and the point of contact

between the tyre and the ground. In the case of positive caster

angle (where the kingpin extension falls ahead of the point

of contact between the tyres and the ground), the wheel is pulled,

as it is the line of application of the force applied to the

axis that passes in front of wheels mid point without taking

the direction of travel into account, and each attempt made

by the wheel to deviate from straight line travel will be counteracted

by the straightening couple generated by the force and by the

rolling resistance of the wheel. With negative castor the wheel

is pushed as it is the line of application of the force applied

to the axis passes behind the mid point of the wheel. Consequently

the best stability condition for straight line travel is obtained

with a positive castor angle. In this case the phenomenon of

"wheel wobble" and the consequent effects on steering

are avoided. The different behaviour of the wheels can be verified

practically by driving the same vehicle in forward gear and

then in reverse. |

|

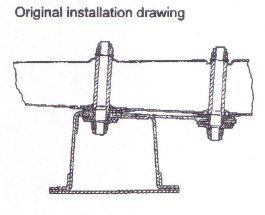

How

does the kit reduce the castor angle?

The method used to reduce the castor angle is to rotate the crossmember

towards the front of the vehicle by providing a precisely engineered

stainless steel packing piece between the front crossmember fixing

points and the underside of the chassis leg. Since the steel packing

has used some of the length of the plain portion of the mounting stud,

a steel collar is supplied with the kit which has to be fitted. In

effect it extends the plain portion of the mounting bolt back to its

original length. Without this collar the rubber mounting pads would

be compressed too much thereby ruining the mounts and the ride quality

- and of course the crushing would give rise to variances in the castor

angle, even between each side of the vehicle. New slightly shallower

high tensile steel locking nuts are provided in the kit to fit the

reduction in useable thread length of the mounting studs.

Steering

rack packing pieces

Because the angle of the crossmember upon which the steering rack

is mounted will have changed slightly in relation to the chassis legs,

the body of the steering rack mast will quite probably no longer align

with the steering universal joint. The steering rack mounts will therefore

have to be packed at the front in order to realign the rack with the

universal joint. Six packing shims are included in the kit.

Can a V8 enthusiast fit the kit?

The B&G Castor Reduction Kit can be fitted by a competent DIY

mechanic but as with most matters relating to vehicles, the modification

does need to be carried out with the right equipment and conditions

and sufficient knowledge, mechanical skill and aptitude. If you have

any doubts whatsoever, the kit should be fitted by a professional

mechanic. B&G estimate that fitting the castor reduction kit requires

approximately three hours work.

Now a few cautionary notes regarding RV8s and Heritage shells and

crossmembers

There is a mistaken belief about that the castor angle on the RV8

is the same as the MGB and V8 and so the castor reduction kit can

also be fitted to the RV8. This is incorrect as the castor

angle on the RV8 is 3 degrees 48 min +/- 54 mins (see the RV8 Repair

Manual AKM7153ENG) so using a castor reduction kit that would remove

3 degrees of castor would leave only 0 degrees 48 mins +/- 54 mins

which is not sufficient. In addition the crossmembers supplied by

the British Motor Heritage plant at Witney, whether supplied individually

or incorporated in new BMH shells, already have a reduced castor angle.

BMH have confirmed that the castor angle reduction was incorporated

on the crossmembers they supply. Therefore any MGB or MGBGTV8 fitted

with a Heritage crossmember, or even in some rare cases fitted with

an RV8 crossmember, should NOT be fitted with a castor reduction

kit.

Prudent check for cracked steering rack mounts While you are

working in this area on fitting the castor reduction kit, it is well

worth checking the condition of the steering rack mounts for any hairline

cracks or more serious fractures. These have been reported in detail

together with the information on the new strengthening gusset supplied

by B&G. See V8NOTE338. A routine check

on the condition of the mounts should be included in your annual servicing

checklist.

The B&G Castor Reduction Kit (AHH6195 CASTOR) is available

now from stock at £29.95 including VAT. The kit includes comprehensive

fitting instructions and detailed diagrams. The Steering Rack Mount

Strengthening Gusset (AHH6195 BRACKET) is also available from

B&G. They can carry out the inspection for you and if cracks are

discovered, supply the gusset and MIG weld it to the mount and crossmember

at their Baldock workshops. For details of the new strengthening gusset

see V8NOTE339. |