|

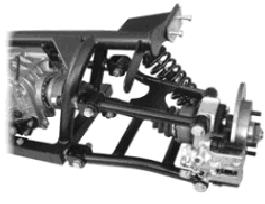

302 Hoyle suspension upgrade kits - a step change in improved handling The improved handling and ride characteristics provided by fitting the front and rear upgrade kits supplied by Hoyle Engineering are reported by V8 enthusiasts as a "marked change" and "handling more like a modern car". So we have taken a closer look at the information available from Hoyle Engineering and gathered comments from Geoff King, a V8 member who has installed the kits on his V8 Roadster Conversion. (Jun 04) The Hoyle suspension upgrade kits are a step change in improved handling for the MGB and its derivatives, including the V8 powered models. There are two kits - a replacement double wishbone, coil-over front suspension system and a complete independent rear suspension with a supporting sub-frame. They provide greatly improved handling and ride characteristics which are comparable with the comfort and precision of more modern cars some 40 years younger. The kits were designed and developed by Gerry Hawkridge of Hawk Cars and John Hoyle, the former owner of NG Cars. Both firms are highly respected specialist car manufacturers producing Cobra replicas and thirties style roadsters based on MGB components.A key feature of these upgrade kits is they have been designed for easy fitting and they maintain the track dimensions. No cutting of the bodywork or the chassis is required and the original components could easily be refitted at a later date. All parts are manufactured from good quality materials to very high standards with powder coating being employed throughout. Every last nut and bolt is included in each kit. Another feature is the suspension systems are adjustable - each telescopic suspension unit is adjustable for ride height and damping, is factory tested, and comes with its own performance report and a three year warranty. For those who want a softer or firmer ride, optional springs are available.  Front suspension with the coil-over damper upgrade. (Photo: Geoff King) Front coil-over suspension kit The kit consists of upper and lower tubular wishbones with dial-in camber adjustment and shims for caster adjustment, coil-over shock absorbers, top turret, rose jointed anti-roll bar links, and all fittings and fixings. The existing lower wishbone pivots and stub axles are retained, while the cross member requires a minor modification by cutting and welding. A powder coated pre-modified cross member can be supplied for an MGB on an exchange basis. Both top and bottom wishbones can be fitted with standard MGB rubber bushes or V8 metalastic, polyurethane or nylatron bushes if preferred. This kit is available for the MGB, MGC, MGBGTV8, and MGBV8 Roadster Conversions. The kit is not available for the RV8, but with additional modification it can also be used on the MGA.  The Hoyle replacement double wishbone, coil-over front suspension system has been specially designed to overcome some of the criticisms of the original front suspension set up and indeed some of the alternative options that have been supplied as upgrades since. The wishbones are fabricated using high grade tubular steel that improves the structural strength and rigidity, the springs are positioned closer to the wheel enabling a much softer spring to be used. This combination together with a high quality damper results in a more supple suspension. The coil-over damper units are specially made with "click" adjustable, re-buildable units with adjustable spring seats to enable the ride height of the car to be changed. The springs supplied are a standard 2.25 inch I/D which are used in a variety of special and race cars. These can be obtained in a wide variety of stiffness and lengths. New anti-roll (sway) bar links are supplied with a spherical joint to provide a more positive reaction. The bottom stub axle bolt is replaced with a special high tensile bolt that has a small flat machined on it which carries two small snail cams. This enables the camber angle to be adjusted simply and quickly. Several shim washers used at the top end of the stub axle provide a small degree of castor adjustment. All fabricated parts and springs are black coated, the dampers are chemically blacked, and the nuts and bolts are bright zinc plated. Standard MGB lower inboard bushes are used for the inboard ends of the new top and bottom wishbones. Polyurethane replacements for normal road use are recommended and can be supplied by Hoyle Engineering. Fitting the front suspension upgrade kit is straightforward It replaces some of the normal MGB components which are: > Four front wishbone arms. > Two spring pans. > Lever arm shock absorber. > Bolts and nuts from the shock absorber mount, top and bottom kingpin assembly. > Front coil springs. > Bump stop and spacers. > "Rubber bush" part of the anti-roll (sway) bar link arms. The lower wishbone pivots and stub-axle assembly are retained. In order to be able to fit a full size spring/damper unit of this type it is necessary to modify the ends of the front cross-member to provide clearance. Hoyle Engineering can do this for you or they can supply a ready modified, powder coated unit on exchange. Some customers carry out the modification themselves, which involves cutting off the end of the cross-member and welding in a gusset. That gusset is also supplied in the kit.The kits are suitable for both chrome and rubber bumper cars. The ride height of a rubber bumper car can be lowered using the spring height adjuster but this will result in a similar amount of bump travel being lost. Independent rear suspension kit The rear suspension kit provides a radical change with a complete replacement of the rigid axle, leaf springs and lever arm dampers with the IRS set up. It has been designed to cope with 400bhp and fit around the existing bodywork, battery boxes, and fuel tank without modification being necessary. The installation adds rigidity to the bodyshell and reduces the un-sprung weight by 55 kilos with the overall weight the same as the standard axle arrangement. Together with the softer springs and high quality dampers, this results in a more supple suspension. Unlike the original system each wheel reacts independently to the change in road surface so not upsetting the balance of the car. The unequal length double wishbones ensure that for hard cornering, the small camber change induced keeps the maximum amount of rubber in contact with the road. Rear end kit provides a radical change with an IRS set up which is simply bolted on The kit consists of a new sub-frame that supports the differential, upper and lower tubular wishbones, coil-over dampers, machined alloy hub carriers, and tiebars (with eight bolt fixing) to the spring eyebolt location. The upper and lower  tubular wishbones are shimmed for camber and tracking adjustment. The shims, in the form of quick-change C washers, can be fitted between the wishbone pivot yokes and the sub-frame to make minor adjustments to camber and tracking. Also included in the kit are stainless steel braided brake hoses, handbrake cables, inner and outer polyurethane wishbone bushes, and all fittings and fixings. The dampers used are the same specification as those used in the front suspension kit. The fabricated parts are black powder coated and the aluminium uprights are anodised. Rear end drive train equipment is readily available from the Ford Sierra and Granada models The differential, drive shafts, hubs, stub shafts, drive flanges and disc brakes are sourced from the Ford Sierra or Granada. The half shafts require shortening to retain the standard track dimension and can be supplied by Hoyle. Ford drive flanges can be used for centre-lock wheels with a bolt-on splined adapter. Hoyle can supply a new flange with MGB stud pattern for bolt-on wheels. |

All these Ford parts can be supplied as new or reconditioned, or can be sourced second-hand very cheaply. There is a range of differential ratios available with 3.1 to 3.9 (Sierra) and 3.3 to 3.6 (Granada). The Sierra unit has a 7inch crown wheel and can cope with engine power of up to 250bhp whilst the 7.5inch unit from the Granada will withstand higher engine outputs. For those with V8 powered cars that want to drive them hard, or use them for track days or competition work, both differentials can be fitted with the standard Ford viscous coupling type limited slip unit. Alternatively a Quaiffe torque biasing LSD could be fitted.

Rear suspension and disc brake conversion. (Photo: Geoff King) Fitting the kit is straightforward once the original axle, springs, and dampers are removed. The replacement unit can be pre-built off the car and then is raised into position. It is attached to the original damper mounts with four bolts, the rear spring front eyebolt mounts via the tiebars with two bolts, and the check strap brackets with two bolts. The stainless steel brake hoses mate with the existing pipework and the dual handbrake cables and their linkages attach to the handbrake drop link. The rear suspension unit can be supplied fully built ready for bolting to your car. The instructions with the kit cover setting up both suspension systems. Hoyle Engineering note that some customers may find this a little daunting with all the variables available - ride height, damping rate, spring rate, and geometry adjustments - in which case Hoyle Engineering say they are always available to discuss and advise on settings based on their own experience and feedback from customers. This kit is available for the MGB, MGC, MGBGTV8, MGBV8 Roadster Conversions, and the RV8. Experience with fitting Hoyle upgrade kits Geoff King (Tartan Red 4309) ) from Kincardineshire mentioned he had fitted both Hoyle suspension upgrades in his article on his conversion project. He changed the front suspension first and found "the "hop, skip and jump" attitude around corners was changed so the car then gave confidence that it will turn in and hold the line without drama. Of course the dampers on the original front end were probably passed their best but I am sure that the improvements I have seen from the Hoyle upgrade kit are much greater than simply fitting new dampers could have achieved. To update the front suspension and brakes I modified the rubber bumper type cross-member with a John Hoyle coil-over damper conversion with unequal length double wishbones replacing the standard lever arm dampers. The suspension has SuperFlex® bushes and is fully adjustable for ride height, damper rate, and caster and camber angles. To complete the front suspension I fitted a 7/8 inch anti roll bar and modified the steering with a 'quick rack' assembly to reduce the number of turns lock to lock". Geoff then moved to the rear suspension. "I fitted the refurbished rear axle, rebuilt with a 3.07:1 ratio crown wheel and pinion, but after less than 500 miles the antiquated live axle and cart springs were sold and replaced with John Hoyle's independent rear suspension kit. Like the front suspension, the IRS kit from John is a high quality product, well designed and manufactured. The ride height, damper rate and camber are all fully adjustable and the bushes are again SuperFlex®. Incidentally, all the bushes used in the front and rear suspension are standard MGB size (front lower wishbone) so future replacements should not be a problem. The total weight of the suspension is slightly more than the live axle but the unsprung weight is much less. The tube axle assembly, springs and dampers weighs close to 100 Kgs, 85 Kgs unsprung. The IRS is approximately 105 Kgs with less than 46 Kgs unsprung. I purchased a refurbished Sierra differential with 3.14:1 CW&P (the highest standard ratio available), exchange-shortened drive shafts and new drive flanges, dust shields, discs, pads, wheel bearings & seals and calliper overhaul kits. A scrap Ford Scorpio donated its hubs, drive shafts and brake callipers; these were refurbished prior to being reused. Assembly of the rear suspension was straightforward with Sierra discs and rebuilt callipers; the completed sub-frame was then offered up and bolted to the chassis. No new holes are necessary; the existing front spring eye, the lever arm damper and check strap mounts are used - 8 bolts in total. A new, heavy duty propshaft to mate the Rover LT77 gearbox to the Sierra diff was purchased from GKN Driveline - suppliers of the original MGB propshafts."What does a V8 feel like on the road with these Hoyle upgrade kits fitted? Geoff King found the difference before and after fitting the Hoyle upgrades quite marked and was clearly pleased commenting "the improved ride and handling on the road with the modern suspension is excellent. Driving the car around the Highland roads is a real joy; no more front wheel patter on rough surfaces, there is very little roll and the back end stays firmly planted to the road. Axle tramp has been eliminated and on hard acceleration the car just squats a little. The brake balance seems perfect with the four pot Rover SD1 callipers at the front and single pot Sierra callipers at the rear". The Hoyle IRS kit offers many advantages "The Hoyle independent rear suspension offers so many advantages it is difficult to know where to start. Comfort has been improved as the suspension has much less unsprung weight and the wheels react to bumps in a more controlled manner. In damp conditions, when traction can be a problem, the wheels may still spin if provoked, but axle tramp is eliminated and the whole car is much easier to control. Axle location is greatly improved and I have just 3 or 4 mm between the tyre and the arch, but know that rubbing will not occur as it could with a live axle".  John Hoyle on his stand at one of the shows he attends with his display of Hoyle suspension upgrade kits. (Photo: Gavin Bailey) "Height, toe in, caster and camber as well as damper settings are all adjustable and although the suspension is too hard to be up to Mondeo comfort standards, there is a big improvement compared with a standard MGB. Time spent experimenting with spring rates could probably improve it even more." Probably for many enthusiasts with modest technical understanding will find dealing with these variables a little daunting and choose to see help from John Hoyle with suggested settings. Supportive and helpful backup service The supportive and helpful response provided by John Hoyle will be something you will value and admire. It's where this small firm stands out as an example to many larger traders if Geoff King's experience is anything to go by. Geoff comments that "I can certainly confirm that John Hoyle is very helpful, I have met him and his wife Barbara several times at motor shows, talked with them on the telephone and have exchanged emails. He replaced my front springs without charge when I felt the items supplied were too hard, and when I had a problem with one of the dampers he immediately resolved the situation - in complete contrast to some other suppliers!" Clearly this important but particularly so when supplier and customer are over 500 miles apart in Geoff's case - it's not so easy just to pop down! Other customers have commented on the splendid support and service from John Hoyle. Gavin Bailey (Glacier White 0199) has met John Hoyle and also reports he is a very pleasant person to deal with. Hoyle kits deserve their growing reputation for improved handling and ride performance These kits deserve their growing reputation for improved handling and ride performance. With the support and service that comes with the Hoyle suspension upgrade kits, the combination is a good quality offering for MGB and V8 enthusiasts. These suspension upgrade kits are available from Hoyle Engineering at Epsom who have a useful website with full information on their kits and a price list. Their contacts for further information are: www.hoyle-engineering.co.uk John Hoyle by email Tel/fax: 0208 393 2555 Copyright

reserved by the V8 Register |

| Footnote

on a wheel size constraint John Hoyle confirms that "information the front suspension will run with 14” wheels, the independent rear suspension (IRS) needs 15” wheels, and the big brake kit will accommodate some 14” wheels providing the ID of the rim is no less than 310mm". All the information about wheels sizes is on their website at: www.hoyle-engineering.co.uk Update: 3.12.07 | |