|

Back

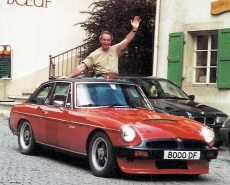

V8 Newsletter published in Safety Fast! This month we have news of recent registrations, an interesting report from David Franklin on his snatching fastest time of the day at a hillclimb in Switzerland last Summer in his "Shopping V8", a brief report of the 50th Anniversary Meeting in New Zealand, and the release of a clutch of workshop notes. Member news New registrations of factory V8s have included details from Jim Lothian (Glacier White 0552) from Middlesex, Richard Horrocks (Glacier White 0947) from County, Tom Fallon (Citron 0954) from Staffordshire, Andrew Yates (Aconite 1172) from Merseyside, Peter Holden (Glacier White 1183) from Warwickshire, Franck Morand (Mirage Blue 1586) from Thailand, Stephen Messenger (Damask 2536) from Hampshire, Barry Hamilton (Green Mallard NNNN) from Northern Ireland and James Lothian (Glacier White NNNN) from Middlesex. V8 conversions include an MGBV8 Roadster from David Lockett (Blue 4212) from the West Midlands with a car reimported from California and converted to LHD and V8 specification in 1975. David also owns another V8 (Red 1577) which is presently dismantled with its running gear fitted to the MGBV8 Roadster! More reimported RV8 registrations have come from James Rudgley (Woodcote Green 0696) from Bedfordshire, John Adams (Woodcote Green 0757) from Gloucestershire with a car obtained from Modern Motoring in Paignton, Devon and Nigel Barker (Woodcote Green 2079) from Hertfordshire. Where "NNNN" is shown above the Car Number or VIN has yet to be received by the V8 Registrar, Victor Smith. John Barnes (Woodcote Green 0636), the V8 Register contact in Wellington New Zealand, mentioned in an emailed note that driving the RV8 down to the NZ 50th Anniversary Rally in Canterbury in early January gave him an opportunity to test his new chip on the engine management system. The RV8 returned around 33mpg at an average of 65mph on the way down and achieved a standing quarter mile time of 16.3 seconds. Sadly the well organised event was dogged by some very unseasonable weather with rain, hail, wind, rain again and some sun! Six members from the UK attended including Piers and Linda Hubbard who had the loan of a blue MGA whilst they were there - a little like home from home it seemed.  John Barnes (Woodcote Green 0636) leaves the starting line at the NZ 50th Anniversary Meeting in January 2002 in Canterbury, New Zealand. (Photo: Piers Hubbard)  Murray Baber (Woodcote Green 0886) essays the motorkana in his RV8 at the 50th Anniversary Rally in Christchurch New Zealand in January 2002. (Photo: Piers Hubbard) Franck Morand (Mirage Blue 1586 originally Glacier White) in Chiang Mai, Thailand has one of the few BGTV8s in France as he keeps it at his parents' home near Clermont-Ferrand. He contacted the V8 Register for information on the choice of oils for the engine, gearbox and back axle as he was arranging a service at long range! A copy of pages 76 and 77 from the BGTV8 Drivers Handbook (AKD8423) was sent out as an email attachment and then by chance Victor Smith was in Kuala Lumpur shortly after, so they made contact by telephone. Chiang Mai is relatively close, just to the north of Malaysia! On learning of the recent release of Volume 6 of the V8 Workshop Notes series, Franck ordered an email copy and later replied - " The copies of Volume 6 and the Rolling V8 Calendar came through very well. I am really impressed with the detailed information in the notes and the compiling work it represents." He then ordered a copy of the updated issue of Volume 5 for the articles in that volume on unleaded fuel for the V8! From the chat over the telephone it was clear Franck is keen to arrange his business visits back to Europe this year to coincide with some of the V8 Gatherings. So we may see him this year at le Mans 24 hour event in mid June, the Club's Silverstone International Weekend at the later date in July and the Goodwood Revival Race Meeting in early September. Franck's registration information shows his BGTV8 has been converted to LHD with a respray in Mirage Blue. He says "it is not near the concours condition of some of the V8s I see in Safety Fast! but it very usable with a number of "sensible improvements". I am a believer in using classic cars and every summer on my return trips to France I drive the V8 for at least 3,000km. My father warms it up for a short drive every month as well!". Franck added he "would have imported another V8 for use in Thailand a long time ago had it not been for the fact it is legally impossible to import secondhand cars to Thailand - even MGs!" David Franklin and the V8 snatch FTD and drive away with a Swiss hill climb award Back in the seventies, one of the most extra-ordinary sights at the Club's annual weekend meeting at Silverstone was David Franklin coming through Woodcote Corner in his BGTV8 on the limit. But what made it even more extraordinary was the V8 was an ordinary road going machine and yet it was dicing with the leading fully modified BCV8 cars! Well the wet conditions, which seemed to be a frequent discomfort at our Silverstone meetings in the late seventies, provided the opportunity for a skilled driver on good roadgoing rubber to get on even terms. In David's case that skill had been honed during many seasons competing in National and European hill climb and sprint championships in various Formula 2 machines. Since then David has competed in many historic racing events and in recent years is frequently seen working wonders with a mouthwatering Ferrari 712 CanAm. His performances at the Goodwood Revival meeting last year in a Ferrari 250LM was another example - anyone standing out at Fordwater on the back of the Goodwood Circuit would have been stunned by the sight of David drifting that glorious machine through that corner and just brushing the apex at around 130mph - a truly extraordinary sight and experience. It was in the Paddock at Goodwood that David mentioned he had popped in fastest time of the day using the "Shopping V8" at a hill climb championship whilst touring in Switzerland last June. Clearly this tickled his sense of fun - trouncing much more powerful machinery is always a pleasure! Here is his note with a report of the event.  David Franklin (Blaze 2177) drives through St Ursanne following snatching FTD at the hillclimb in 2001 with terry Osborne repeating the applause taking in 1974! (Photo: Debbie Franklin) "In the seventies I was lucky enough to spend many years hill climbing in Europe, and Switzerland in particular with Formula 3 and then Formula 2 single seater racing cars, My team manager in those days was the well known MGB racer and BCV8 competitor, Terry Osborne. In 2001, the Swiss MG enthusiast Marcel Schaub invited us to compete in a round of the British Sports Car Cup in Switzerland held at the St Ursanne les Rangiers hill climb. I had competed there eight times in the seventies so knew the hill pretty well! Two years ago, we had competed in a round of their championship in Austria at a hill climb called Silvetta using the BGTV8 - normally my wife's shopping car - which we drove over, competed, won the class and then drove home again. A total of 3,000 miles! So when the chance of competing with them again last June arose it was far too tempting to turn down, and it was closer to home! In 2001 the event was called the Jo Siffert Memorial Hill Climb, with scrutineering and practice on Saturday, and two timed runs on the Sunday. As in the seventies, team manager Terry Osborne, - "Ozzy" to his friends! - could not resist the chance of returning and meeting old friends, visiting restaurants and generally having a good time! We drove down in two cars, Ozzy in a 2001 Mondeo due to his advancing years, and Deb and myself in the V8. We arrived in glorious sunshine on the Thursday afternoon after a good run down from the overnight boat from Portsmouth to Le Havre. A couple of beers in the village of St Ursanne sitting under a parasol was really great but little did we know that this would be the last sunshine we would see until we left on Monday morning! Friday was raining and we did a couple of reccy runs up the hill which leaves the picturesque village of St Ursanne on the river Doubs in the Jura mountains, and winds up the valley for three miles to join the main road to Delemont and Basel at the end of the hillclimb at les Rangiers. It is all on public roads, it is very fast for the main part but with three first gear hairpins at the top. In the seventies we would average 98 mph from a standing start over this course in a two litre March BMW F2 car!! Saturday was again raining, still this made scrutineering easy as it was in the open! I could not be bothered to removed the rubber bumpers or spare wheel and tools from the boot for practice, so ran in heavyweight specification! A really good dinner followed on Saturday night with all the Swiss crowd which made-up for the rotten weather. Out of 140 entries in the programme, only eighty or so were listed after practice as the weather forecast had been so terrible for the whole weekend, many had not turned up at all! Sunday was still raining, now nonstop since Friday morning. On the first runs in the morning, the road was in good condition despite the odd "river" running across the track. However just before the hairpins there was an oil slick running on the racing line all the way to the finish! At the parc ferme after the finish, I walked down to speak to my good friend Eddy Wyss (who was driving a beautiful Abarth 1300 and running about ten cars in front of me) and I asked him what he thought about the oil? He replied what oil! Only to find when his oil pressure warning light came on during his return down the hill that it was his car which had deposited the oil! For the rest of the weekend he was known as "Oily Eddy". Our time in the V8 was very good, thanks to the fancy Yokohama tyres we were running which were ideal for the conditions. For the second runs on Sunday afternoon there were less competitors. It seemed they had either fallen-off or had just got fed up with the weather! For our runs, as we arrived at the oil on the hairpins, we came upon oil granules and a surface like glass! Had it been left alone, the oil would have been washed away together with the cement dust or anything that might normally soak-up the oil, but not in those rainy conditions. As we walked to the village hall that Sunday evening for the prize giving, it actually stopped raining! The result was a little embarrassing - fastest time of the day outright! We had clocked 2min 40.41 for FTD some 0.48 seconds ahead of Jacques Joliat from France with an F2 GRD and then ten and twelve seconds ahead of two Porsches! Our average speed was just over 66 mph!".  Terry

Osborne (Glacier White 1480) "riding mechanic" on the

back of David Franklin's F3 Ensign in St Ursanne back in 1974 -

repeated in the BGTV8 in 2001! (Photo Debbie Franklin) Terry

Osborne (Glacier White 1480) "riding mechanic" on the

back of David Franklin's F3 Ensign in St Ursanne back in 1974 -

repeated in the BGTV8 in 2001! (Photo Debbie Franklin)Footnote: Team Manager Ozzy insisted we ran the BGTV8 without the rubber bumpers, spare wheel and tools for the competition runs. We compromised and took off the front bumper, so we were semi-lightweight! The "Shopping V8", 8000 DF, has had a wonderful competition career spanning 25 years. After winning the BCV8 Championship in 1981, it was third overall on the Tour Espagna in 1999, took the class record at the Colerne sprint the same year and still gets driven to and from meetings. Oh! - and the sunroof was open all the way back to le Havre from Switzerland on the Monday! Now a couple of photos of John Targett (BRG 1022) from Sussex who lives in the US and races an historic MGB Roadster in a series known as the "Past Masters".  John Targett in his ultra low MGB Roadster at Watkins Glen in the US Past Masters series". (Photo: Dana Moreland)

V8 Workshop Note 245 Small steps and giant strides in the handling department The suspension package on the BGTV8 was showing its age even when the V8 was launched in 1973 and by today's standards the handling demands skill and attention. Ken Drake (Citron 1057) from Berkshire provides this note on how he has made a series of improvements to the handling on his V8. (Dec 99) When I acquired my BGTV8 in June 1987, it was suffering from a lack of use as it had been virtually laid up for seven years. So although this had preserved the bodywork wonderfully, a certain amount of recommissioning had to be done. However once this had been accomplished, much as I appreciated the straight line performance, I found the handling hairy to say the least with an alarming amount of body roll on cornering. Fortunately, Ron Hopkinson introduced his handling kits in 1988 and I was one of his first customers. The kit I obtained consisted of a rear anti-roll bar which has to be secured to the floor of the spare wheel well together with a thicker front anti-roll bar. They were fitted by the V8 specialist, Geoff Allen at Abingdon (Editor: now retired). With the back of the car anchored to the axle, the improvement in handling was quite dramatic with body roll reduced considerably. In my opinion that kit remains good value today particularly as it is slightly cheaper (at £99.50) than it was then. So far as driving is concerned, I have the misfortune to live in the grandly titled Royal County of Berkshire where I'll swear the roads are the most neglected in the country. With the new handling kit installed, I still experienced a rather jarring ride over the poorly surfaced and pot-holed roads which abound in the county. So in 1991, I arranged with Geoff Allen to supply and fit the Moss Dynamic Suspension System. This handling kit replaces the front lever arm dampers with top wishbones and incorporates telescopic dampers inside the replacement coil springs. Once fitted, this system made a really worthwhile improvement to ride quality and eliminated the bump-thump at low speeds. Again I felt the £400 for the kit was money well spent. However as the local roads continued to deteriorate and the Council decided to invest its road budget in road humps or sleeping policemen, which play havoc with the car's suspension system, rather than in adequate road maintenance. Things got so bad that when speed bumps were installed in my own road, there was a risk my wig might become dislodged as the V8 lurched over them - I hasten to add this joke is for the benefit of all those rumourmongers! So when British Motor Heritage Engineering introduced their Performance Suspension Assembly in 1997, based on the front cross-member developed for the MG RV8, my interest was aroused. The assembly was a complete replacement for the original cross-member incorporating double wishbones with adjustable Koni telescopic dampers within the coil springs, maintenance free ball joints instead of kingpins and ventilated disc brakes with 4 piston callipers. All very appealing but also quite costly. So I canvassed opinions of a couple of members of the V8 Register who were fortunate to own both an original BGTV8 and an RV8, on the relative merits of the RV8 set up. Strange to relate both members were independently non-committal. On reading the magazine reports of the |

BMHE Performance

Suspension Assembly they appeared to have been written by people

who one might feel had vested interests. No demonstration cars with

the conversion installed were available. Crown Classic Cars is run by brothers Jason and Tony Payne who have exclusive hands-on experience with MGs and had already fitted a number of these RV8 assemblies. On visiting them I was reassured to find their workshop and yard full of Jaguars and TRs as well as MGs and found their workmanship to be superb and reasonably priced - a rare combination these days, usual disclaimer applies!! Fitting the kit took a day and when I collected the V8, Jason warned me to go carefully until the new brakes had bedded-in. So it was with some trepidation that I set off for home down the busy Chertsey Road in rain that soon became torrential, but the first nervous jabs on the brakes provided instant reassurance that the improvement was immediately obvious. It has only got better since. So with the memory of the previous set-up still fresh in my mind, I wrote these impressions of the new RV8-style system. The improvement in ride quality is quite amazing with the damping, even on the softest setting, most impressive with none of the previous floating action after hitting a bump. To be fair some of that previous floating action could have been attributed to the previous dampers being exhausted after eight years of pounding on the appalling roads in Berkshire. The steering feels somewhat lighter at low speed and wonderfully responsive and positive at higher speeds thanks to 1990s technology rather than the previous set up which first saw service some 50 years ago. Before the conversion to the RV8 set up there had been some vibration transmitted through the steering wheel on all but the smoothest of roads, which I had been told was due to the tyres degrading with age, but with the new set up this has gone completely. Tight bends can now be taken in complete confidence as the steering is so compliant and responsive with none of the previous tendency to put up a bit of a fight and run wide if the surface was a bit rough or bumpy. Visually the ride height of the car is unaltered but the front track is marginally but perceptibly wider giving the car a slightly macho stance. Was it worth it? Well the RV8 assembly costs £1,821 and the fitting time and costs will depend on whether or not the exhaust manifolds have to be removed to undo and refit the four chassis-crossmember mounting bolts. Fortunately mine did not have to be removed. So for around £2,100 my MGBGTV8 has been brilliantly transformed into a car that is more enjoyable, mote relaxing and safer to dive. Admittedly it is fairly costly, but the RV8 assembly represents excellent value for money in my opinion as it achieves improvements in so many areas without affecting the inherent character of a classic car. In fact it probably brings the MGBGTV8 even closer to the late John Thornley's vision of creating "the poor man's Aston Martin". In any case I can always console myself with the thought, in Quentin Wilson's words, that I have saved myself "shed loads of money" by not buying an RV8 in its entirety! V8 Workshop Note 240 Trouble with the original "top hat" battery terminals Julian Fecitt (Black V8 1350) from Lancashire joined the V8 Register in September 2001 and found his BGTV8 had a problem so contacted the V8 Register for help. Amongst the responses was this note from Victor Smith (Harvest Gold V8 1089). (Dec 01). The message from Julian Fecit outlined the difficulty - "when the car is hot and the accelerator is pressed, the engine cuts out. It will restart but cuts out again. Eventually it will restart but continues to misfire. Leads and plugs look fine - does this indicate a carburettor problem or is it a well documented "characteristic of the model?" Well in terms of characteristics of the model Victor Smith offered the following suggestion as a possible cause of the misfiring. "I have found I have had problems with my BGTV8 misfiring when picking up from low revs and on a couple of occasions the car has refused to fire up again after refuelling at a filling station. I eventually traced the problem to the battery terminals which on the original installation at the Factory were a "top hat" pattern with a screw through the centre of the cap down into the terminal. Initially just moving the cap on the terminal and re-tightening was sufficient to overcome the problem but having found the cause of the misfire problem, I got into the routine of cleaning the inside of the caps and around the terminals with a smear of Vaseline each Spring when the car came back on the road after a Winter lay-up. This was coupled with the usual annual service and grease up and cleaning or replacing the points and a check on the gap with my dwell meter with the machine warmed up." Well this year at the Hook Norton Brewery, where I was collecting polypins of real ale for the V8 marquee at MG Car Club's International Weekend meeting at Silverstone, my V8 just would not fire up. As you will know the twin 6 volt batteries on the chrome bumpered V8 are located in a black hole under a metal panel beneath the rear seat - not the easiest place to get to or work in! On disconnecting and inspecting the caps it dawned on me that the chamfered profile of the inside of the cap no longer matched the chamfer of the battery terminal - in effect only a very small part of the two surfaces were in contact and most of that was through the screw from the top! I realised that spirited cleaning of the inside of the caps with emery paper over past years had put more abrasion on the outer edge than the innermost part of the inside of the cap - hence the changed profile. With most of my light luggage and tackle for Silverstone removed from inside the car and my head stuck down in the gloom of the battery compartment, I cleaned out the accumulated crud from the innermost part of the cap. On replacing the caps and connecting up the terminals, the V8 fired up beautifully and pulled away in low revs in second and third without any hint of misfire. I have since decided I have had enough of those wretched top hat caps. I obtained a set of open top clamp fittings, cut off the top hats and fitted the clamps to my battery leads. I feel a great deal happier with them and the more so when I mention a further concern. I have found some replacement 6 volt batteries seem to be just a fraction taller than the original equipment. When you have battery leads with top hat connectors with screws from the top, the clearance between the underside of the removable black metal access panel and the screws on the top of the tapered caps is extremely tight! In fact dangerously so! This is not a satisfactory situation at all because a short between the panel and the positive terminal would very soon produce a red hot panel - the inferno that might follow in your garage quietly overnight does not bear thinking of.! So check your battery terminals and the clearance with the access panel as soon as you can! Well the response from Julian Fecitt two weeks after my note was sent was "Thank you for your email. Since changing the batteries, cleaning up the battery leads and giving the car a good run over the hills, it seems to be behaving." He later mentioned "it was running like a dream - but I know this is tempting fate!" RV8 Workshop Note 109 Problems with the zip on the RV8 rear screen Victor Rodregues (Oxford Blue 1621) from Switzerland reported a difficulty with the zip around his rear screen. This note explains how he resolved it together with some further comments from John Barnes (Woodcote Green 0636) in Wellington New Zealand. (Aug 01) I had a difficulty with the zip on the rear window of my RV8. It became unserviceable and it was no longer possible to close the rear window. I called the V8 Registrar to see if there were any ideas on repairs or fitting a new zip, or whether any member had faced this problem before and how was it solved? My initial contacts with local hood repair specialists in Switzerland were disappointing - their answers were either that it would be necessary to fix the rear window so it could not be opened and consequently the hood could not be dropped, or I would have to install a new hood!! The V8 Registrar replied relaying information provided by Clive Wheatley indicating that the hood could be repaired in the UK. Clive Wheatley would be able to arrange that, but the hood would have to be removed from the car and sent over to England as a parcel with a freight company (like Fedex or UPS). Clive warned me that, unlike the hoods on the earlier MGBV8 Roadsters, it was not easy to remove the RV8 hood and considerable care would be needed. Alternatively I could deliver the car to the hood repair specialist in England - quite a journey from North East Switzerland! Well I did some local research in Switzerland and found several firms specialising in soft tops for motor cars. The fourth specialist company I contacted made a fantastic and professional job maintaining the rear window intact and they did not need to remove the hood from the car. They managed with very good hands and their special tools to repair the zip by exchanging the very vulnerable piece that brings the two separate parts of the zip together. The total cost for the repair work was the equivalent of £60.00 which I was very pleased with. Now here are my tips for RV8 enthusiasts facing a similar problem with the zip on their rear window: Research - make enquiries and seek the opinions of several local car hood specialists or qualified furniture restorers. Procedure - try to make sure the small zip cursor piece can be professionally replaced before you decide it is necessary to remove the hood from the car. Hood replacement - it is definitely not necessary to think about a replacement hood even if you live a long way from England! Caution - if you are not familiar with zip repair technicalities, never try and do the repair yourself as it could become a very expensive experience! Finally I was advised to always keep the hood up whenever the car is parked long term with the window closed. At least once a year you should lightly lubricate the zip all round with a suitable product. Also Clive Wheatley advised that RV8 enthusiasts must take care with operating and maintaining the zips around the rear screen to avoid possible damage. Later we received some further comments from John Barnes (Woodcote Green 0636) from Wellington in New Zealand: "Before the zip is zipped down, it is a good idea to release the front clips holding the hood to the screen which releases the tension on the hood fabric including the rear window. It should be zipped right the way down so that when the window is folded over and stored at the rear of the parcel tray, there is no strain on the zip. When zipping up or down, the zip should be treated gently." V8 Workshop Note 239 Ride height and bumpers Peter Holden (Glacier White V8 1183) retired from circuit racing a Midget a few seasons ago and thought about getting a BGTV8 which he could use for the occasional historic navigational event. He contacted the V8 Register seeking some guidance on ride heights and bumpers. This note is based on the reply provided by Roger Parker. (Sept 01). Pete Holden's e-mail to Roger said "I have a couple of questions regarding the BGTV8 as I am looking at buying a car towards the lower end of the price range with the emphasis on a tidy and usable car which I can prepare for the occasional historic navigational event, so I definitely do not want to "waste" an exceptional vehicle! Of course chrome bumpers would be nice but I am already finding that chrome bumper cars in my price range (£5,000 to £6,000) suffer from excessive "tin worm". However I thought that as rubber bumpered BGTV8s certainly appear (from my brief surfing of the internet) to command lower prices. Are the following ideas feasible, even though the second is probably a heresy!! Ride height - do rubber bumpered V8s have a higher ride height than the chrome models and can they be lowered? I have seen Brown & Gammons advertise a lowering and handling kit for rubber bumpered vehicles which I presume would do the job or are V8s in some way different? Now for the heresy - if I remove the rubber bumpers, can I replace them with a one piece front and rear valence panels in glass fibre similar in style to those fitted to the MGCGTS? There are front views of several cars on page 30 of September's Safety Fast! but no rear shots. Can you advise a way forward?" Well the reply from Roger Parker was both punctual and straightforward in his usual way. The answer to your first question is the BGTV8 was about an inch higher than the same model year for four cylinder chrome bumper cars and so when the rubber bumpers arrived the four cylinder cars saw a rise of about one and half inches whilst the V8 saw a minuscule additional half inch or so. The reality is that this much smaller difference almost means that both models can almost be treated as the same. Certainly the actual configuration between four and eight cylinder cars is similar except that the spring rates at the rear are considerably higher to cope with the effect of the V8 torque. The adoption of spacer blocks is therefore not advised because spacing the axle from the springs will increase the torque leverage effect and may cause adverse consequences. If it is felt lowering is necessary, using re-cambered springs is much better. The removal of the rubber bumpers and their replacement with anything that has a connection with the chrome bumper set up (Sebring panels are chrome bumper cars without chrome bumpers) means you will face the same problem. Looking at the front and rear installations on rubber bumpered models: Front bumpers - the rubber bumpers are mounted on very large and heavily modified brackets fitted to the front ends of the original chassis rails. These encroach significantly on what would be the area below and above the bumper line. This also extends rearwards towards the radiator. These ends and the rearwards extensions will have to be removed to provide access for either chrome bumpers or Sebring panels. In addition the rubber bumper brackets that sit above the oil cooler platform completely block the fitting of a chrome grille. Even if just the first couple of inches of this is removed to allow access to mount a chrome grille the remainder will be as visible as a large wart through the slats! Perhaps only the late plastic eggbox style of plastic grille centre would partially restrict this view. Front wings were next. On rubber bumpered cars they have great big holes where the front wings on chrome bumpered cars have smaller holes in which the side light and indicator unit is fitted. The hole on rubber bumper wings is far larger than the lamp unit fitted to the chrome bumper wing. So conversions from rubber to chrome set up require either a change to a chrome bumper wing or welding in a shaped steel section from a chrome bumper wing to fit the lamp unit. Rear bumpers - the same sort of large rubber bumper mounts are fitted to the ends of the chassis legs in just the same way as the front. These need to be cut away to provide access for the chrome bumper and a Sebring panel. In addition, you will find there is a void below each rear light which is occupied by an upswept section of rubber bumper. On chrome bumper cars there is a round section of rear wing. It is that section of the chrome bumper rear wing that would have to be welded in. A number of companies do rubber to chrome bumper conversion kits which include the parts needed top cover the problem areas mentioned above. The work is such that by the time you have got as far as completing this conversion, fitting genuine chrome bumpers is a relatively small additional job, so the use of Sebring panels would only save only a small amount of work together with the cost of the chrome bumpers and brackets. The solution as I see it is to persevere with the search for the type of car you really want because the cost of converting a rubber bumper car will near enough put the overall cost in much the same level as going for the chrome bumper car to start with." Pete Holden subsequently contacted the V8 Register to report he had acquired a chrome bumpered BGTV8 (Glacier White 1183), previously registered by Paul Carrier in North Yorkshire. Pete noted "the car has had a colour change from its original Citron. This was carried out by a previous owner when having a substantial overhaul to the bodywork at Beer of Houghton back in the 1980s. The car is having "remedial" work carried out at present - mainly mechanical with a little welding and fitting a front valence in place of a glass fibre spoiler. I should have the car back on the road during December as my daily transport." |