43

Noisy

fuel pump

Roger Parker, who has close contact with an RV8 and runs

an MGBV8 EFi Roadster conversion (Green 4092), provides this useful article. (Nov

90)

Since

the fuel pump has a well documented history from its use in other cars, some of

the known faults that can occur can be simply diagnosed. One common problem has

been with a noisy fuel pump. This is usually down to the inherent characteristic

of these pumps of not being able to draw fuel well. Once they have an unrestricted

supply and delivery route, the pumps will happily deliver up to 4.1bar (60psi)

when operated at normal system voltage, nominally 13.5 volts. When the supply

is restricted, especially in the tank to pump feed, the pumps become very noisy

and can resemble the sound of a Black and Decker drill. Very hot conditions can

also induce this noise.

The common cause for restriction in the fuel lines

is within the filters. As the accumulation of debris from the petrol storage tank

is a common difficulty and in severe cases can very quickly block up a filter.

Replacement of the pre-pump filter is the first step, followed by the feed line

from pump to fuel rail. If subsequently excess noise returns and it is found the

filter is silting again, it will require the removal of the fuel tank and a comprehensive

clean out.

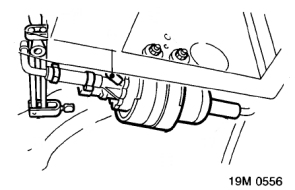

Examination of the fuel pump will reveal that the inlet has

a 12mm bore size, whilst the delivery side uses the common 6mm bore size. The

choice of the different sizes reflects the acknowledged weaknesses of these pumps

to draw fuel and it comes as a surprise to see that the RV8 uses a stepped hose

to downsize the feed pipe from the tank to pump from 12mm to 6mm. This is without

doubt to allow the original pattern of fuel tank sender unit fitted which includes

the fuel feed pipe to the later MGB models to be used with the RV8.

From

personal experience with these EFi systems in MGBV8 conversions long before the

launch of the RV8, I know that the system overcomes the potential deficiency because

the positioning of the fuel pump at such a low position relative to the fuel tank.

This provides the assistance of gravity to compensate. However this will make

fuel filter changing more important.

|

Source: RV8 Repair Manual

AKM7153ENG Fuel System, Repairs, page 9.

The regulated working pressure

of the fuel system is 2.5 bar above internal manifold pressure. That means that

measured externally the fuel pressure will be regulated to between 1.8 and 2.5

bar depending on engine load and throttle position. Since the pump operates at

4.1 bar when supplied with normal system voltage levels there is a significant

excess margin of pump performance.

All

V8 Rover Vitesse and 2.0 litre injected Maestro and Montego models operate with

an inline fuel pump resistor to cut down the voltage supplied to the pump in much

the same way as a ballasted coil system operates. This was used to reduce the

speed and consequent noise of the fuel pump. The fuel pump resistor is a standard

Rover part DRC 3017 and I have incorporated this into several injected V8 conversions

I have built. For those RV8 owners who consider that their pumps are intrusive

and that other solutions have not worked, then this offers a way of achieving

some improvement.

The resistor is wired into the electrical supply to the

pump to provide a mirror image of standard Rover systems. To achieve this an additional

wire is taken from the starter motor to the pump side of the resistor so that

when the engine is being cranked, a full 12 plus volt supply is delivered to the

pump. This ensures that if the battery is low or the starter motor is drawing

a higher current, then as much power as possible is fed to the pump to provide

fuel supply. Once the engine is running and the cranking disengaged, the direct

supply is also disengaged and the power supply is only via the resistor. One other

advantage of introducing the resistor into the system is that the reduced rotational

speed of the pump leads to a longer life. |