100

Catalyser - overheat sensors, overheat ECU

& warning light

The cat overheat sensors linked to an associated cat overheat

ECU and a cockpit panel warning light, were an addition to the

RV8s exported to Japan and a number of members with reimported

RV8s appear to have experienced difficulties with them. Our

anonymous contributor explains how to approach this problem.

(June 01)

The

RV8s manufactured for the Japanese market have a number of small

but significant differences from the UK specification models

with regard to both the 6-light warning panel (situated immediately

below the radio console) and the catalytic converter itself.

Although there are known to be some variations between the two

basic warning light layouts [for the UK and Japan specification

models], the normal arrangement reading left to right across

the panel is as follows:

UK

specification:

Handbrake

Brake fluid level

Hazard flasher

Oil pressure

Engine ECU MIL

|

Japan

specification:

Catalyser overheat

Handbrake & brake fluid level

Hazard flasher

Oil pressure

Seat belt |

In

the UK specification models of both MG RV8s and MGFs, there

is no facility for alerting the driver to an overheating catalyser.

On the other hand, the owners of Japanese specification models

will have no indication of a fault within the main engine ECU

since these models lack a MIL (Malfunction Indicator Light).

From a personal standpoint I would have preferred to see the

Japanese specification arrangement on all RV8s with the added

benefit of the Engine ECU MIL replacing the seat belt warning

light.

There

are really only three reasons for the Cat Overheat light to

illuminate:

| o |

The

catalyser temperature is at or above 900oC with the attendant

risk of component meltdown (literally!). |

| o |

The sensor(s) is or are faulty. |

| o |

The

Cat Overheat ECU and/or its associated wiring are in some

way defective, leading to a short circuit. |

| o |

The Cat Overheat ECU and/or its associated wiring are

in some way defective, leading to a short circuit.

|

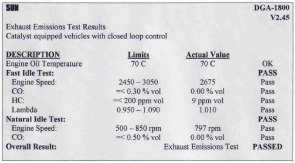

So

what is the remedial action? Go to the nearest MG Rover or Land

Rover MOT testing station which is staffed by competent individuals.

Ask for the foreman and do not be fobbed off with some inexperienced

19 year old. (These types seem to abound in many motor trade

establishments. They are not "cool"; they and other

similarly inexperienced people are potentially lethal and must

be kept away from your vehicle at all costs). Ask for a print-out

of your exhaust emissions from their Sun DGA 1800 Engine Analyser.

This is an integral part of the MOT test and, if asked for separately,

should cost no more than £10. If the readings are as set

out in the panel below, then your catalytic converter is working

correctly. The sensors (part number WDN 10001) are not available

in the UK. However, they are obtainable from MG Rover in Japan

through HS Imports (tel: 01278 789024) and cost around £150

each!

Changing

the sensors may not of course solve the problem. The fault could

lie within the Overheat ECU and/or the associated wiring. The

main difficulty in tracing this kind of fault is the lack of

information relating to these sensors and their ECU. Most sensors

are thermistors of the negative temperature co-efficient (NTC)

type which means their resistance falls with increasing temperature.

What the diagnostician needs to know are the resistance values

at particular points over a given temperature range. Neither

MG Rover in the UK nor their |

For a larger copy of these test results - table

dealerships

appear to have this information which of course is crucial to

the testing of any such component.

In short, if the exhaust gases are correct, then the catalyser

is doing its job properly. After all, owners of UK specification

models do not have the benefit of an overheat warning light

and would only know that they had a problem when some other

physical evidence became apparent for example the smell of very

hot metal, coupled with a marked change or degradation in both

fuel economy and overall performance. As I said earlier, once

the temperature of the catalyser rises beyond 900 C, "meltdown"

will almost certainly occur. This involves components literally

melting and fusing together such that the exhaust flow will

be physically impeded. This condition is frankly so unusual

that I have been unable to find anyone with first-hand evidence

of a genuinely overheating catalyser where the vehicle was in

normal everyday use. A lean mixture or the use of unleaded fuel

of less than 95 RON could well give rise to an overheat condition

in the catalyser and elsewhere - for example a higher than normal

coolant temperature. In this connection it is worth noting that

the relevant handbooks and manual state "95 RON MINIMUM".

This statement implies that fuel with a RON of less than 95

may well be available in countries outside the UK. Personally

I have always used 98 RON super unleaded - cost cutting can

be a dangerous obsession!

In

essence then, if your exhaust emissions are correct and all

other physical evidence indicates no obvious malfunction, simply

remove the warning light bulb. One can of course go down the

route of changing the sensor(s), changing the Overheat ECU,

changing the associated wiring etc. However, this is the path

of madness. The whole exercise is likely to prove both unrewarding

in terms of time and effort, and very expensive indeed. In the

end all

you will have achieved is the elimination of the fault in a

component that was almost certainly installed with the intention

of protecting the catalyser from possible abuse or damage through

the use of inferior grades of fuel that are in any case absent

from the civilised World. This of course explains why all petrol

fuelled motor vehicles destined for the Hone Market (UK) do

not have Cat Overheat Sensors and their associated engine management

components fitted as standard equipment. Quite simply it would

be an unnecessary, expensive and wholly superfluous.

Acknowledgements:

In preparing this workshop note, I should like to thank both

John Corten-Miller and Phil Cooley of the Corten-Miller Performance

Centre at Boston in Lincolnshire, who gave me a great deal of

help and advice with both this and other issues of a diagnostic

nature relating to the MG RV8. Although their operation will

handle most aspects of motor vehicle engineering and servicing,

their particular area of expertise lies in specialist diagnostics

aimed at improving motor vehicle performance. They are agents

for Weber, Lucas, Bosch, ASNU (specialist in injector diagnostics),

Superchips (based in Buckingham) and deal with both fuel injected

and normally aspirated engines. I am more than happy to recommend

their services. Corten-Miller Garages can be contacted at Eaudykes,

Friskney, Boston, Lincolnshire and on 01754 820341 and at email |